Essential Oil Extraction Equipment

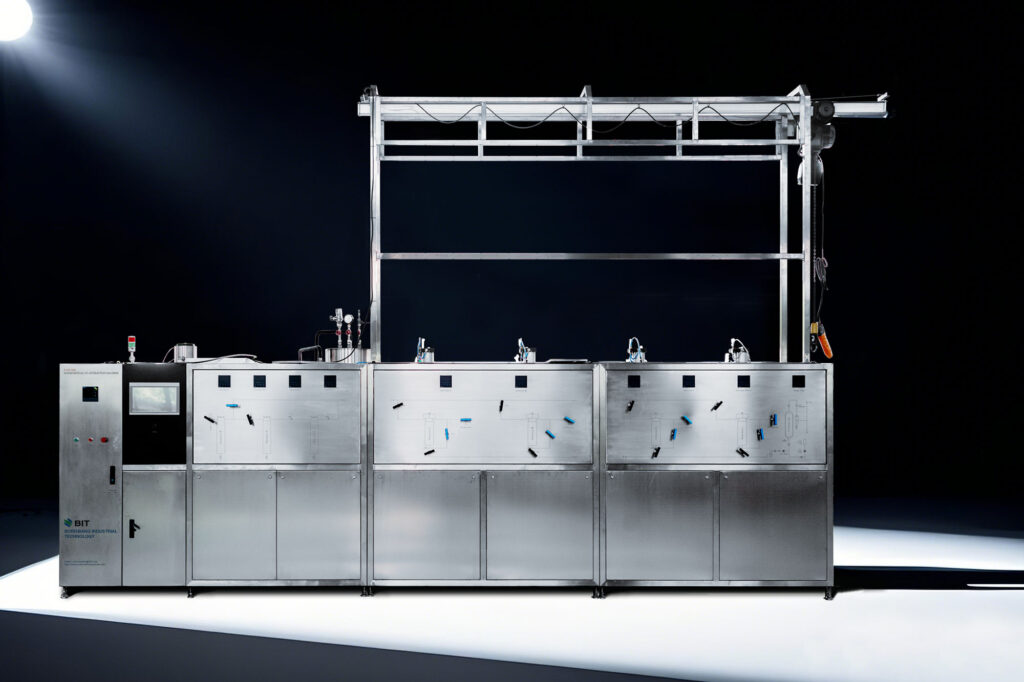

50L×4 Supercritical CO2 Extraction Equipment

High-Efficiency | Green | Intelligent Extraction Solution

50L×4 supercritical CO2 extraction system is a medium-scale industrial solution designed for efficient and clean extraction of plant-based active compounds. Equipped with four 50-liter extraction vessels and three 20-liter separation vessels, it supports flexible operations such as alternating or parallel extraction. This setup is ideal for extracting high-value materials like essential oils, herbal actives, CBD from hemp, functional food ingredients, and natural fragrances.

1. System Components and Technical Features

Main Components:

- Extraction Vessels: Four 50L high-pressure chambers for continuous or batch operation.

- Separation Vessels: Three 20L vessels for staged separation of substances by polarity or volatility.

- CO2 Circulation System: Includes high-pressure plunger pump, condenser, and flow control loop for efficient CO2 reuse.

- Control Panel: PLC-based touchscreen interface offering real-time temperature and pressure monitoring.

- Safety System: Equipped with overpressure protection, safety relief valves, and emergency shutdown functions.

Key Technical Advantages:

- Customized extraction workflows for various raw materials.

- It supports 24/7 continuous operation and is ideal for commercial batch processing.

- Features automatic pressure-temperature control and CO₂ recovery system.

- Built with GMP-compliant stainless steel (SUS304/SUS316L).

2. Technical Specifications

| Item | Specification |

|---|---|

| Extraction Vessel | 50L × 4 |

| Separation Vessel | 20L × 3 |

| Max Pressure | 45 MPa |

| Temperature Range | Room Temp ~ 85°C |

| Control System | PLC + Touchscreen Interface |

| Material | SUS304 / SUS316L Stainless Steel |

| Heating Method | Electric Heating / Hot Water Circulation |

| CO₂ Recovery | Automatic |

| Safety Features | Overpressure Protection, Auto Venting |

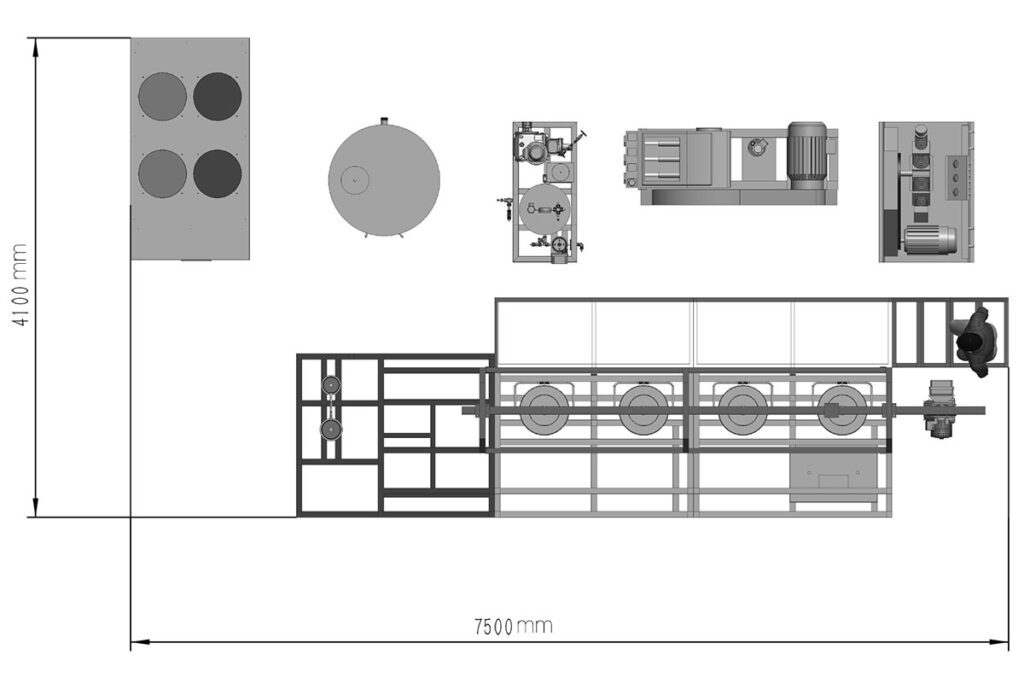

Layout Diagram of 50L×4 Supercritical CO2 Extraction Equipment

3. Real-World Applications

Example 1: Rose Essential Oil Extraction

At 30 MPa and 40°C, dried rose petals were processed using the 4-vessel system. Within 90 minutes, highly aromatic oil with over 98% purity was collected—retaining volatile and heat-sensitive compounds. The extract is suitable for perfumes, aromatherapy, and skincare products.

Example 2: Icariin Flavonoids from Epimedium

Using alternating multi-vessel operation, the system extracted flavonoids from Epimedium powder. The gradient separation system collected different polar fractions separately, improving the yield and concentration of the active compounds. It supports formulation R&D for herbal pharmaceuticals.

Example 3: CBD Extraction from Industrial Hemp

At 30 MPa and 40°C, the 50L×4 system continuously processed hemp flowers and leaves. Three separation vessels collected waxes, terpenes, and CBD-rich oil based on boiling point differences. The final product meets export-grade quality standards with no solvent residues.

4. Wide Application Fields

- Essential Oil Extraction (Lavender, Rose, Sandalwood)

- Herbal Actives Extraction (Flavonoids, Alkaloids, Saponins)

- Food Additives and Functional Extracts (Capsaicin, Caffeine)

- CBD Extraction from Industrial Hemp

- Aromatherapy & Natural Cosmetics Manufacturing

5. After-Sales & Technical Support

- On-site factory visits and free sample extraction testing

- Operation manuals, video guides, and remote startup assistance

- Free spare parts replacement within one year for non-human damages

- Long-term support for process optimization and technical upgrades