Borisbang Industrial Technology (Nantong) Co., Ltd.

Supercritical CO2 Extraction Machine

Efficient Essential Oil Extraction Equipment

Calculator for Essential Oil CO2 Extraction Machine

* Note: Material should be dried (moisture content <10%) and properly ground for optimal extraction efficiency

What is Supercritical CO2 Extraction?

Supercritical CO2 extraction is an eco-friendly and efficient method widely used in food, pharmaceuticals, and cosmetics. By adjusting the CO2 temperature and pressure, it precisely extracts target compounds such as essential oils, active ingredients, and alkaloids.

Advantages of Supercritical CO2 Extraction

- High Purity Extraction: Avoids solvent residues and preserves active ingredients.

- Strong Controllability: Adjusting temperature and pressure allows precise extraction.

- Eco-friendly and Safe: CO2 is recyclable and causes no pollution.

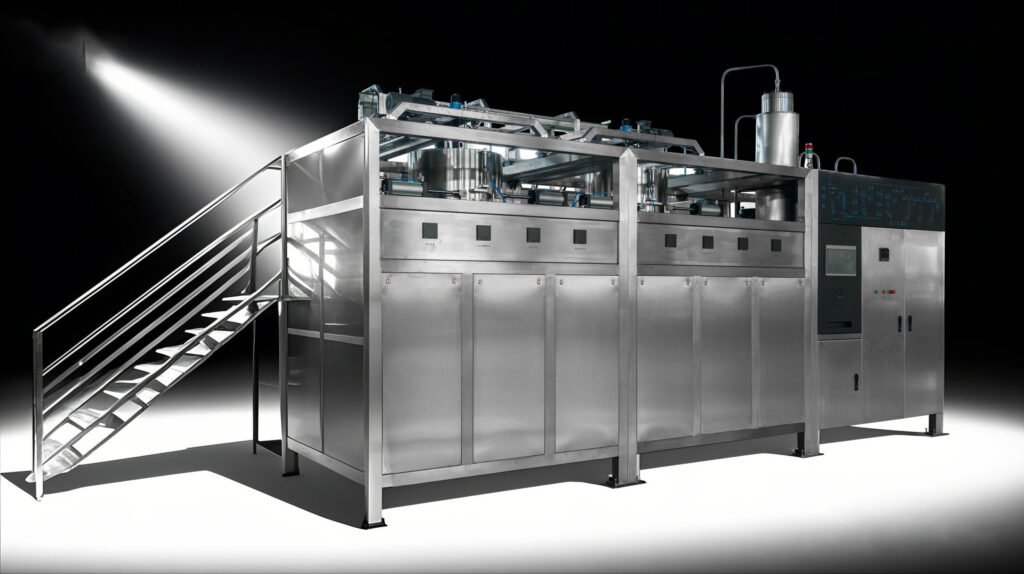

BIT Fully Automated Supercritical CO2 Extraction Machines

BIT offers highly integrated, supercritical CO2 extraction machines suitable for different production scales, including benchtop, small, and industrial models.

Types of BIT CO2 Extraction Machines

- Tabletop CO2 Extractor: Ideal for laboratory research, with an extraction volume of 10ml to 200ml. [Learn More]

- Small CO2 Extraction Machine: Suitable for small-scale production, with a capacity of 500ml to 10,000ml.

- Industrial CO2 Extraction Machine: Designed for large-scale production, ranging from 20L to 9000L. It includes frame-type and platform-type structures.

Understanding CO2 Extraction Equipment Grades [Read More]

How to Choose the Right Supercritical CO2 Extraction Machine?

Consider the following factors when selecting a machine:

- Extraction Vessel Size: Determines daily batch extraction capacity.

- Extraction Pressure Level: Higher pressure enhances extraction but increases cost.

- Number of Separators: Using at least 2–3 cascade separators improves product quality.

- CO2 Recovery System: Recommended for systems over 10L to reduce operating costs.

Biomass reference value for 24H extraction capacity: moisture content: <10%, specific gravity: 0.25KG/L

Case: Efficient Rose Essential Oil Extraction

Supercritical CO2 is ideal for premium oils like rose, lavender, and rosemary.

Process:

- Preparation: Use fresh/dried rose petals.

- Temperature: Maintain 30-40°C to protect aroma.

- Pressure: Apply 9-12 MPa for fragrance molecules.

- Separation: Dual separators remove waxes and pigments, yielding pure oil.

Compared to steam distillation, CO2 preserves heat-sensitive compounds, making it perfect for luxury skincare and perfumes.

4 Key Tips to Improve Supercritical CO2 Extraction Efficiency

1. Control the Extraction Temperature

- Increase Temperature: Enhances the extraction of waxes and resins, boosting yield.

- Lower Temperature: Reduces wax content, improving oil purity.

2. Adjust the Extraction Pressure

- Low Pressure (7–12 MPa): Best for extracting flavors and spices.

- Medium Pressure (12–25 MPa): Ideal for essential and fatty oil extraction.

- High Pressure (≥30 MPa): Suitable for highly polar active compounds.

3. Set the Optimal CO2 Flow Rate

- Increasing the flow rate speeds up extraction and enhances the solvent capacity.

- Excessive flow rate reduces interaction with materials and increases CO2 consumption.

4. Use Co-solvents for Better Efficiency

- Adding 3% ethanol doubles lipid solubility.

- In pepper oil extraction, 10% ethanol increases yield by 230%.

Discover how our supercritical CO2 extraction machines can improve product purity, efficiency, and sustainability. For more insights on the technology and its benefits across industries, check out our blog Supercritical CO2: A Green Technology Transforming Industries.

ABOUT US

Borisbang Industrial Technology Co., Ltd. has been designing and producing supercritical fluid systems for more than 30 years.

BIT’s laboratory, pilot, commercial and industrial supercritical CO₂ extraction machines are sold worldwide. China’s market share exceeds 80%. Exports to the United States, Canada, Argentina, the United Kingdom, Italy, Switzerland, France, Poland, Spain, Hungary, New Zealand, India, South Korea, North Korea, Taiwan, Sri Lanka, Morocco and other countries.

NEWS & EVENTS

-

Supercritical CO2 Extraction of Spice Essential Oils

Spice essential oils are natural aromatic oils obtained from spices such as seeds, fruits, flowers, roots, and bark. They are widely used in everyday products, including foods, seasonings, beverages, pharmaceuticals, and fragrances. The quality of spice essential oils largely depends on how gently and efficiently they are extracted, especially when the aroma compounds are sensitive […]

-

High-Quality Pumpkin Seed Oil Production via Supercritical CO2 Technology

1. Advanced Fluid Technology for Botanical Research Supercritical CO2 (SC-CO2) extraction is the gold standard for researching heat-sensitive lipid compounds. For laboratories focusing on functional oils, the ability to precisely control the fluid state is paramount. This study utilizes pumpkin seed oil—a complex matrix rich in PUFAs (76%+), Tocopherols, and Phylloquinone—to demonstrate the precision and […]

-

Supercritical CO2 Extraction of β-Carotene from Sweet Potato

Introduction to β-Carotene Extraction β-Carotene is a natural pigment widely found in plants. It is approved as a food additive. It is also known for its antioxidant activity. Therefore, it attracts strong interest in the food and health industries.However, traditional extraction relies on organic solvents. This causes solvent residue. It may also damage pigment quality. […]

FAQ – Frequently Asked Questions

1. What Products Can Be Extracted Using Supercritical CO2?

Supercritical CO2 extraction is suitable for essential oils, active compounds, medicinal extracts, and food ingredients, such as:

- Essential Oils: Rose, lavender, rosemary, lemon, etc.

- Food Compounds: Caffeine, piperine, capsaicin, tea polyphenols.

- Medicinal Ingredients: Herbal extracts, alkaloids, polyphenols, sterols.

2. How Does Supercritical CO2 Extraction Compare to Traditional Solvent Extraction?

| Factor | Supercritical CO2 Extraction | Traditional Solvent Extraction |

| Solvent Residue | No solvent residue, 100% natural | Possible organic solvent residue |

| Temperature | High-temperature extraction may degrade active ingredients | High-temperature extraction, may degrade active ingredients |

| Eco-friendliness | CO2 is recyclable and environmentally friendly | Some solvents may harm the environment |

| Extraction Efficiency | Targets specific compounds with high precision | May extract multiple impurities, requiring additional refinement |

3. Is an Additional Solvent Required?

CO2 alone can extract most compounds. However, adding ethanol or water as a co-solvent can improve efficiency for highly polar compounds like polyphenols and flavonoids.

4. Does CO2 Extraction Affect Product Flavor?

No. CO2 extraction occurs in a low-temperature, oxygen-free environment, preserving the extract’s natural aroma and flavor. This makes it ideal for premium food, spices, and cosmetics.

5. Are CO2 Extraction Machines Expensive to Maintain?

Maintenance costs mainly include replacing seals, cleaning pipelines, and maintaining the CO2 recovery system. Overall, operational costs are low since CO2 is recyclable, reducing consumption.

6. How to Select the Right CO2 Extraction Machine?

Consider capacity, pressure range, number of separators, and CO2 recovery system. If unsure, contact us for expert recommendations.