Over 30 years of design and production of supercritical CO₂ extraction Machine

Supercritical CO₂ Extraction Machine Manufacturer

Essential Oil Extraction Equipment | GMP Certified Industrial Extraction Solutions

Supercritical CO2 extraction machine manufacturer

SINCE 1989

Borisbang Industrial Technology Co., Ltd. has more than 30 years of experience in producing supercritical CO2 extraction machines. It is mainly committed to the research development and production of supercritical CO2 extraction equipment and has formed a series of medium and small-scale test (production) machine production capabilities. BIT distributes its products nationwide and exports them to the U.S., South Korea, Southeast Asia, and beyond. Businesses use our systems to extract and differentiate active ingredients in medicine, food, flavors, and fragrances.

Core Advantages

BIT Supercritical CO₂ Extraction Machine: Clean Process & High-Efficiency Extraction Technology

Our equipment is designed for the pharmaceutical, food, cosmetics, and fragrance industries, catering to the extraction of herbal essential oils and active ingredient separation. Key advantages include:

- Low-Temperature, Non-Destructive Extraction: Preserves plant active ingredients intact (e.g., CBD, astaxanthin).

- 99% CO₂ Recovery Rate: Reduces production costs and meets environmental standards.

- Precision Pressure Control: Accuracy up to 0.1 MPa, adaptable for both laboratory and mass production applications.

- Dual Safety Certification: ASME + PED compliance ensures industrial safety.

Applicable Materials

- High-Value Plant Extracts: Hemp CBD oil, Ganoderma spore oil, sea buckthorn seed oil, frankincense oil.

- Fragrance & Food Processing: Ginger oil, sandalwood oil, decaffeinated spice oil, hop extract.

- Functional Ingredients: Astaxanthin, rice bran oil, tea tree seed oil, olive pomace oil.

WHY CHOOSE US

More than 30 years of supercritical fluid technology research and development | 100+ engineers team

Preferred supplier for pharmaceutical/food/cosmetic industries in more than 70 countries around the world

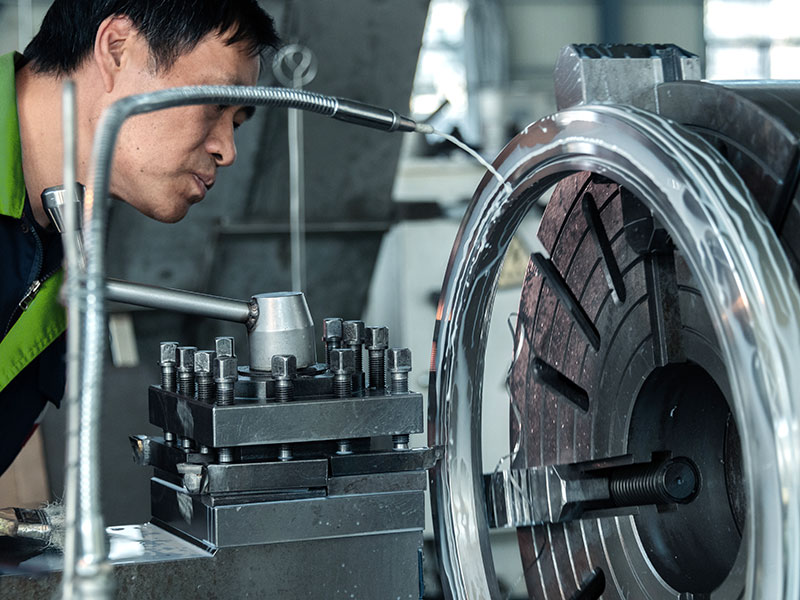

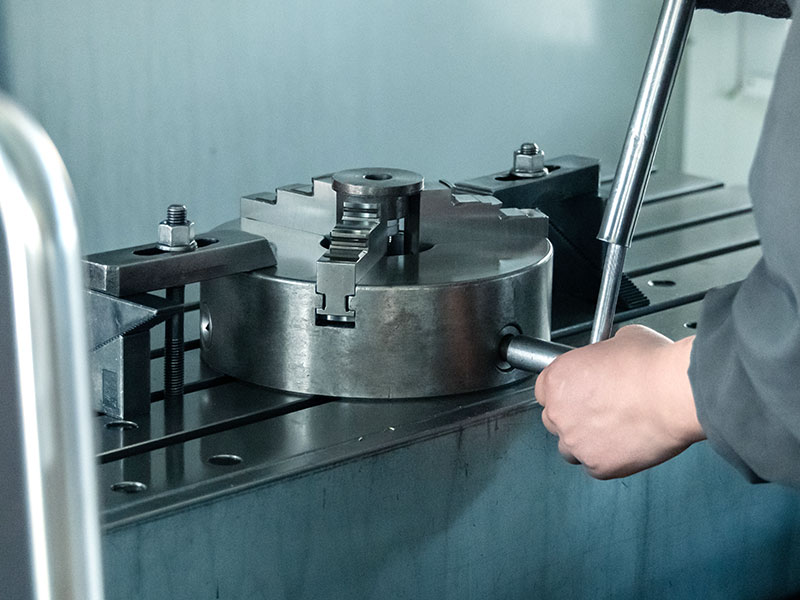

We have a strong technical team of over 100 professional engineers and have collaborated with experts from China’s top universities and research institutions for more than 30 years. We offer a full range of solutions, including:

- Full-Scale Equipment Range: From 5L laboratory models to 5000L industrial-scale supercritical CO2 extraction systems.

- Customized Solutions: Support for GMP and ISO-compliant facility development.

- Comprehensive support for the entire process, from R&D to commercial production.

Internationally Certified Extraction Equipment Supplier | Compliance Assurance

- Global Market Access Certifications: CE (EU), ASME (USA), PED (Pressure Equipment Directive)

- Quality Management System: ISO 9001 certified with full-process traceability

- Customer Service Commitment: 48-hour response time, installation training, and lifetime maintenance

NEWS & EVENTS

-

Supercritical CO2 Extraction of Spice Essential Oils

Spice essential oils are natural aromatic oils obtained from spices such as seeds, fruits, flowers, roots, and bark. They are widely used in everyday products, including foods, seasonings, beverages, pharmaceuticals, and fragrances. The quality of spice essential oils largely depends on how gently and efficiently they are extracted, especially when the aroma compounds are sensitive […]

-

High-Quality Pumpkin Seed Oil Production via Supercritical CO2 Technology

1. Advanced Fluid Technology for Botanical Research Supercritical CO2 (SC-CO2) extraction is the gold standard for researching heat-sensitive lipid compounds. For laboratories focusing on functional oils, the ability to precisely control the fluid state is paramount. This study utilizes pumpkin seed oil—a complex matrix rich in PUFAs (76%+), Tocopherols, and Phylloquinone—to demonstrate the precision and […]

-

Supercritical CO2 Extraction of β-Carotene from Sweet Potato

Introduction to β-Carotene Extraction β-Carotene is a natural pigment widely found in plants. It is approved as a food additive. It is also known for its antioxidant activity. Therefore, it attracts strong interest in the food and health industries.However, traditional extraction relies on organic solvents. This causes solvent residue. It may also damage pigment quality. […]