Borisbang Industrial Technology (Nantong) Co., Ltd.

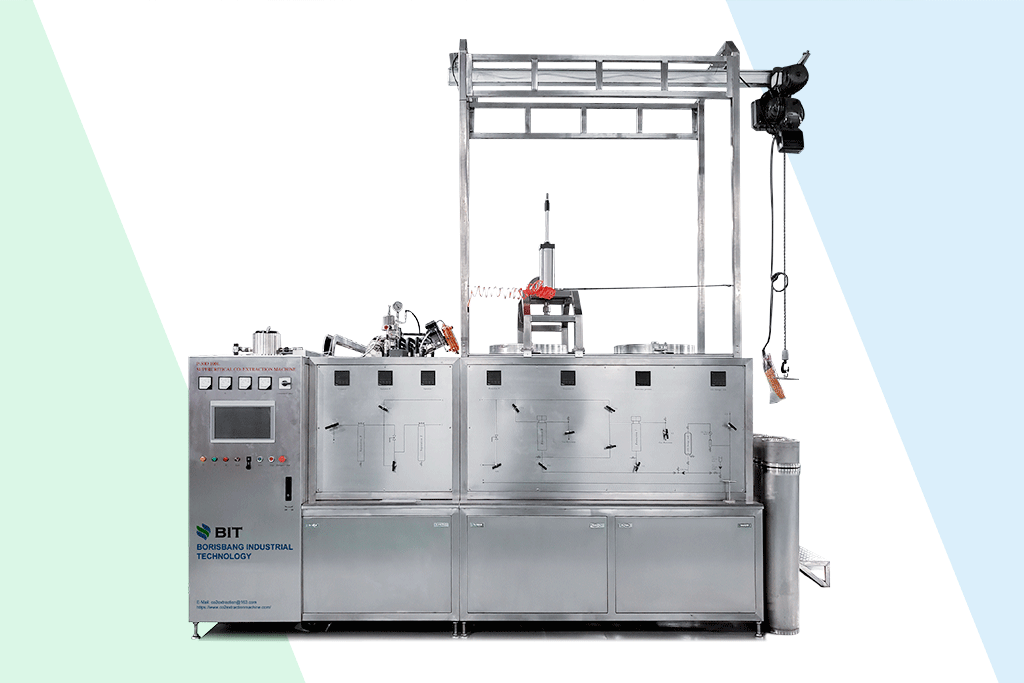

Pilot-Scale Supercritical CO2 Extraction Equipment

Efficient, Scalable Solutions for Small-Batch Natural Product Manufacturing

Summary

Pilot-scale supercritical CO2 extraction equipment offers a clean, precise, and scalable method for producing high-purity plant extracts. Positioned between laboratory and full-scale production, these systems are ideal for startups, contract manufacturers, and R&D facilities. This article outlines the definition, advantages, key features, technical specifications, and real-world applications of pilot CO2 extraction systems.

Table of Contents

1. Definition

2. Key Features

3. Technical Specifications (Example: 50L×2)

4. Application Case: Lavender Oil Extraction

5. Advantages

6. Frequently Asked Questions

7. Conclusion

What Is Pilot-Scale Supercritical CO2 Extraction Equipment?

Pilot-scale supercritical CO2 extraction equipment is designed for small-batch processing and product development. These systems typically feature extraction vessels ranging from 20L to 100L, allowing users to scale up from laboratory testing while avoiding the cost and complexity of large-scale machinery.

More classification of supercritical CO2 extraction equipment [Read More]

Used widely in:

- Essential oil extraction (e.g., lavender, tea tree, frankincense)

- Cannabis and hemp oil processing (in legal jurisdictions)

- Natural flavor and fragrance production

- Nutraceutical and herbal extraction

- Cosmetic active ingredient isolation

[Further Reading] Pilot scale supercritical CO2 extraction of carotenoids from sweet paprika: Influence of particle size and moisture content of plant material

Key Features of Pilot CO2 Extraction Systems

- High Extraction Efficiency

Supercritical CO2 enables precise targeting of active compounds, with high yield and minimal degradation. - Customizable Configurations

•Dual extraction vessels (e.g., 25L×2, 50L×2)

•2–3 separator vessels for compound fractionation

•Co-solvent compatibility for polar compound extraction - Energy-Efficient Design

•Integrated heat exchange and CO2 recycling

•Automated pressure and temperature regulation

•Low CO2 consumption with optimized circulation - GMP-Ready Materials

All components in contact with raw materials are made from SUS304 or SUS316 stainless steel for pharmaceutical and food-grade compliance.

Technical Specifications (50L×2 Example)

| Parameter | Specification |

|---|---|

| Extraction Volume | 2 × 50L vessels |

| Operating Pressure | Up to 45 MPa |

| Max Temperature | Up to 85°C |

| Separator Units | 2–3 (12–20L per unit) |

| CO2 Flow Rate | 10–20 kg/h |

| Control Interface | PLC with touch screen |

| Build Material | SUS304 / SUS316 stainless steel |

Application Case: Lavender Essential Oil

We use a 25L×2 pilot-scale CO2 extraction machine to process around 30 kg of dried lavender daily. The system delivers high-purity essential oils with no solvent residues, ideal for certified organic cosmetics.

Advantages of Pilot CO2 Extraction Equipment

- Scalable production without large infrastructure investment

- Lower operating costs than industrial-scale systems

- Fast processing cycles (2–4 hours typical)

- Solvent-free and high-purity extracts

- Semi-automated or fully automated control for ease of use

❓Frequently Asked Questions (FAQ)

Q1: What is the typical capacity of a pilot CO2 extraction system?

A: Most pilot systems range from 20L to 100L per extraction vessel, ideal for small production runs or testing.

Q2: Is this equipment suitable for cannabis or hemp oil extraction?

A: Yes. If compliant with local regulations, pilot systems are excellent for producing high-quality cannabinoid extracts.

Q3: How long does a typical extraction run take?

A: Average cycles are between 2 and 4 hours, depending on the material and process parameters.

Q4: What certifications are supported?

A: Systems can be customized to meet CE, ASME, GMP, and other regulatory requirements.

Conclusion

Pilot-scale supercritical CO2 extraction systems provide a reliable, cost-efficient, and clean extraction method for small-batch natural products. With flexible configurations, robust construction, and easy scalability, these systems are an ideal solution for manufacturers seeking to bridge the gap between R&D and commercial production.

Trusted by Global Clients

Our CO2 extraction systems have been sold to over 30 countries, including the USA, Germany, Thailand, and Australia. From start-up brands to well-known herbal extract manufacturers, our customers trust us for:

- Reliable equipment performance

- Excellent technical support

- One-stop turnkey solutions

- Remote installation guidance and training

Supercritical CO2 Extraction Market Report

Contact Us

Looking for the right supercritical CO2 extraction equipment for your business? Contact us today for custom quotes, technical consultation, and free extraction process evaluation.

Email: [email protected]

WhatsApp/Phone: +86-134-8515-5519