Summary

This article provides a complete 2025 guide to the cost of supercritical CO2 extraction machines, including a breakdown of price ranges by equipment scale—Lab-Scale, Pilot Scale, Industrial, and Customized. It compares manual vs. automated systems, explains how to choose the right machine based on processing needs, and outlines operating and maintenance costs. Ideal for businesses in the CBD, essential oil, or plant extract industries, this guide helps investors make informed decisions before purchasing a CO2 extraction system.

Table of Contents

1.Introduction

2.How Much Does a Supercritical CO2 Extraction Machine Cost?

3.Manual vs. Automatic CO2 Extraction Systems

4.How to Choose the Right CO2 Extraction Equipment

6.Final Thoughts: Making the Right Investment

7.FAQ - Supercritical CO2 Equipment Cost

Introduction

When investing in a supercritical CO2 extraction machine, understanding the cost structure is crucial. Whether you’re a CBD oil startup, an essential oil manufacturer, or scaling up to industrial production, the right equipment selection directly affects yield, quality, and ROI.

This article explores pricing by machine type, compares manual vs. automated systems, and outlines essential factors to consider when choosing a CO2 extractor.

How Much Does a Supercritical CO2 Extraction Machine Cost?

Pricing varies significantly based on machine capacity, automation level, and customization. Here’s an updated breakdown based on the standard classification of equipment:

| Machine Type | Capacity Range | Typical Applications | Estimated Price (USD) |

|---|---|---|---|

| Lab-Scale | 1L–5L | R&D labs, small-batch formulation | $20,000 – $50,000 |

| Pilot Scale | 10L–50L × 2 | Pre-production, small commercial use | $50,000 – $120,000 |

| Industrial Scale | 100L–1000L+ | Continuous high-volume production | $150,000 – $1,000,000+ |

| Customized Equipment | Custom size/design | Specialty plants, high-efficiency ops | Quoted per project |

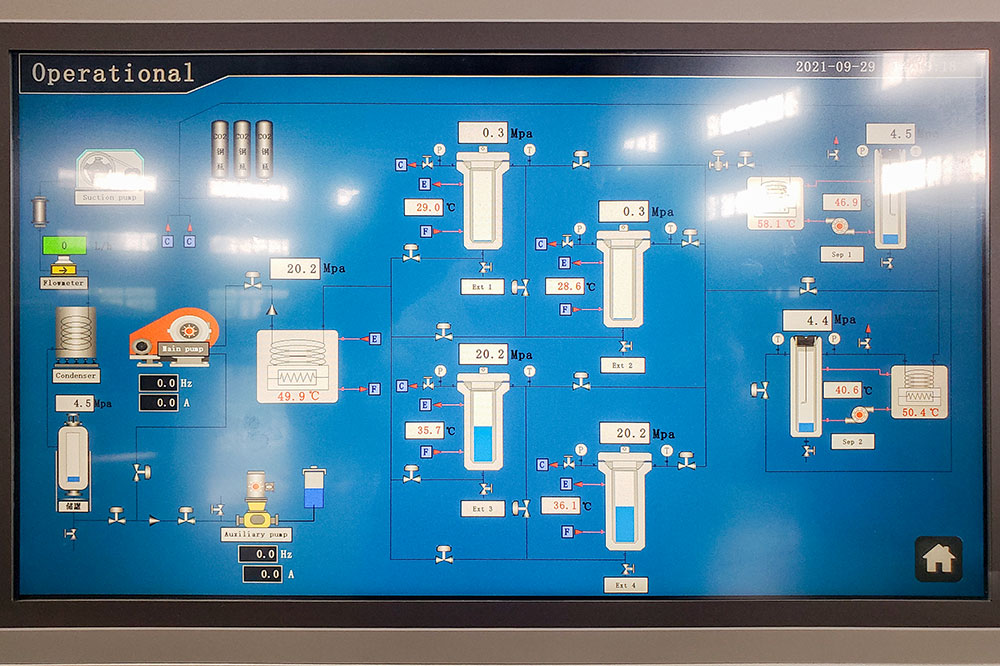

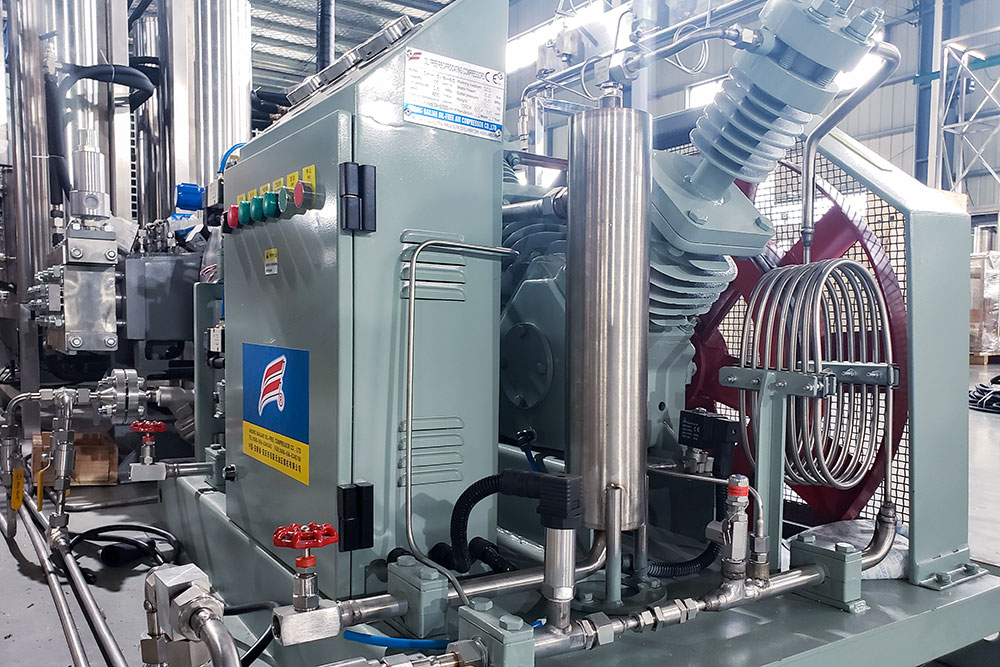

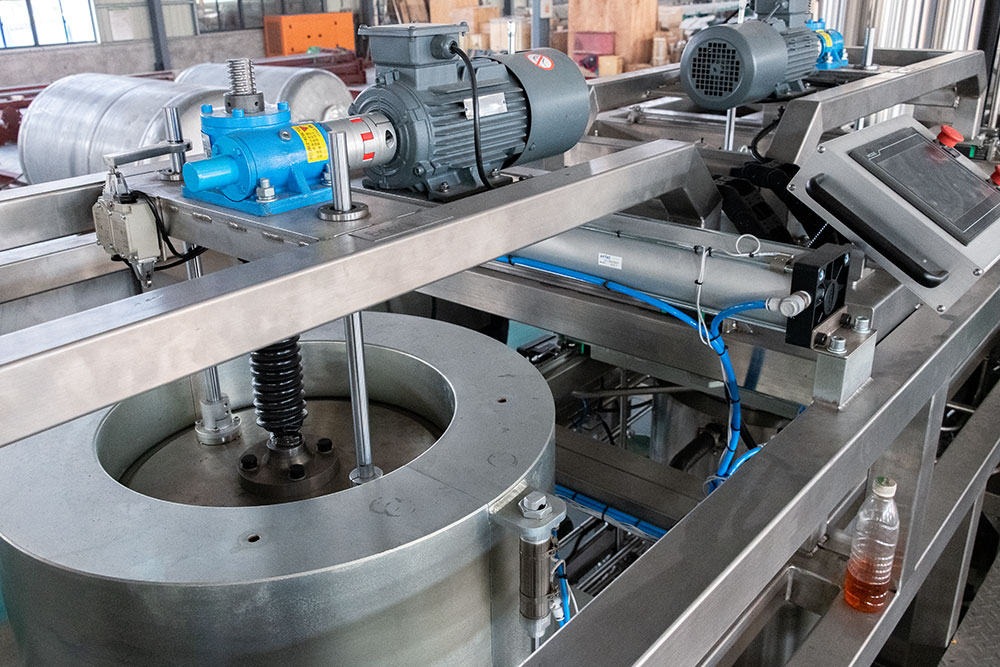

⚠Note: The price typically includes extraction vessels, separators, CO2 pumps, heaters, chillers, and control systems. Auxiliary components like air compressors and chillers may be extra.

Manual vs. Automatic CO2 Extraction Systems

Automation greatly affects both upfront cost and ongoing efficiency.

| Feature | Manual System | Automated System |

|---|---|---|

| Initial Cost | Lower | Higher |

| Operation | Manual adjustments, operator-led | Programmable, auto-controlled |

| Consistency | Operator-dependent | High batch-to-batch consistency |

| Skill Requirement | Requires skilled technicians | Easy to train and monitor |

| Best For | R&D, low-throughput facilities | Production-scale CBD or essential oils |

✅ Recommendation: For operations running 8+ hours/day, automation improves safety, reliability, and labor efficiency.

How to Choose the Right CO2 Extraction Equipment

Beyond machine cost, you need to assess your daily processing needs, raw materials, and facility conditions:

Key Questions:

- How many kilograms of raw material per day?

- Number of operating hours per shift?

- CBD-rich hemp? Essential oils? Pharmaceuticals?

- What are the compliance needs (GMP, CE, ASME)?

- Site infrastructure: electricity, ventilation, water cooling?

| Daily Throughput | Suggested Capacity | Recommended System |

|---|---|---|

| < 5 kg | 5L–10L | Lab-Scale / Manual |

| 10–30 kg | 25L × 2 / 50L × 2 | Pilot Scale / Semi-Auto |

| 50–100 kg | 100L × 2 / 300L × 2 | Industrial / Fully Automated |

| > 200 kg | 500L × 2 / 1000L × 2 | Industrial / PLC Controlled |

👉 Best-Selling CO₂ Extraction Machines for Essential Oils [Read More]

Operating and Maintenance Costs

Even the best machines require regular care. Here’s a snapshot of what to expect:

Daily Operating Costs:

- Electricity: High-pressure pumps, heaters, chillers

- CO2: Use of recycled or external liquid CO2

- Air Supply: For pneumatic valves or controls

⚡ Power usage varies by capacity; pilot-scale systems cost around $5–$15/hour to operate.

Maintenance Checklist:

- Gaskets, seals: Replace every 6–12 months

- Valves and pumps: Inspect every 1000–2000 hours

- Filters and nozzles: Clean after each run

- Sensors and probes: Calibrate monthly

Staff Requirement:

- Manual system: Needs a full-time operator

- Automated system: One person can monitor multiple units

Final Thoughts: Making the Right Investment

When choosing your supercritical CO2 extraction machine, consider not just the upfront cost, but also:

- Total Ownership Cost (TOC)

- Labor requirements

- CO2 and energy efficiency

- Maintenance and expandability

- Batch size flexibility

For growing businesses or GMP-regulated products, fully automated industrial-scale or customized supercritical CO2 extractors deliver optimal performance and long-term savings.

FAQ – Supercritical CO2 Equipment Cost

Q1: Is supercritical CO2 extraction suitable for CBD startups?

Yes. Though initial investment is higher than solvent extraction, it’s safer, solvent-free, and better for full-spectrum quality.

Q2: Can I upgrade from manual to automatic control later?

Some modular systems support automation upgrades. Confirm during purchase.

Q3: What utilities are needed for installation?

Electricity (typically 380V 3-phase), cooling water, CO2 supply, and safety ventilation.

Trusted by Global Clients

Our CO2 extraction systems have been sold to over 30 countries, including the USA, Germany, Thailand, and Australia. From start-up brands to well-known herbal extract manufacturers, our customers trust us for:

- Reliable equipment performance

- Excellent technical support

- One-stop turnkey solutions

- Remote installation guidance and training

Supercritical CO2 Extraction Market Report

Contact Us

Looking for the right supercritical CO2 extraction equipment for your business? Contact us today for custom quotes, technical consultation, and free extraction process evaluation.

Email: [email protected]

WhatsApp/Phone: +86-134-8515-5519

You can view other models of supercritical CO2 extraction equipment [View More]