Borisbang Industrial Technology (Nantong) Co., Ltd.

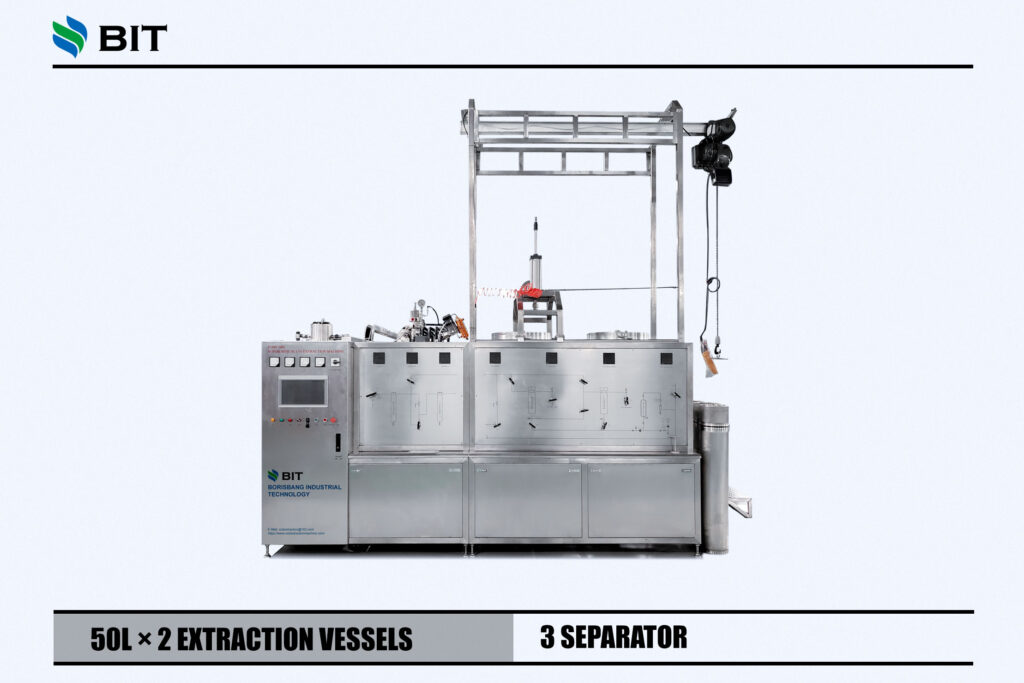

100L CO2 Extraction System (50L×2)

Efficient, Scalable Solutions for Small-Batch Natural Product Manufacturing

Summary

This article introduces the 100L (50L×2) supercritical CO2 extraction equipment, a medium-capacity, dual-vessel system designed for efficient and solvent-free extraction of essential oils, cannabinoids, and plant-based actives. It covers key features such as high-pressure tolerance, multi-stage separation, optional PLC automation, and typical applications across the cosmetic, nutraceutical, and herbal industries. The article also provides detailed technical specifications, a step-by-step extraction workflow, FAQs, and reasons to choose this equipment. A contact form is included to help potential buyers easily request a quote or technical support.

Table of Contents

1.Introduction

2.Key Features

3.Technical Specifications

4.Typical Applications

5.CO2 Extraction Workflow

6.FAQ – Frequently Asked Questions

7.Optional Configuration

8.Why Choose Us?

Introduction

The 100L (50L×2) supercritical CO2 extraction equipment is a medium-capacity industrial system designed for the efficient extraction of essential oils, cannabinoids, herbal actives, and nutraceutical compounds. Utilizing clean and solvent-free supercritical CO2 technology, this dual-vessel system offers precise temperature and pressure control, multiple separation stages, and optional PLC automation. It is widely used in industries such as cosmetics, food supplements, CBD oil, and functional plant extracts.

The 100L (50L×2) supercritical CO2 extraction equipment is a medium-sized machine with two extraction kettles, each with a capacity of 50L.

The two kettles work in turns, and it is best to have a carbon dioxide recovery system to help recover carbon dioxide.

Key Features

- Dual 50L Extraction Vessels: Operate simultaneously or alternately to increase productivity and batch flexibility.

- High-Pressure Tolerance: Handles up to 40 MPa to extract both non-polar and mildly polar compounds.

- Multi-Stage Separation System: 2 to 3 separators enable the collection of essential oils, waxes, and volatile fractions.

- Optional PLC Automation: Manual, semi-automatic, or full-touchscreen control systems available.

- Food & Pharma-Grade Materials: Constructed with SUS304 or SUS316L stainless steel for hygiene and corrosion resistance.

- Eco-Friendly Solvent Recovery: Optional CO2 recycling reduces emissions and operational costs.

Technical Specifications

| Parameter | Value |

|---|---|

| Extraction Vessel | C02 high-pressure pump & Co-solvent pump |

| Separator Vessel | Volume: 29L × 2 + 20L, Working Pressure: 20 MPa |

| Pump | C02 high pressure pump & Co-solvent pump |

| Operating Temperature | 40–85°C |

| Material Construction | SUS304 / SUS316L |

| Heating Method | Electric + PID Temperature Control |

| Control System | Manual / Semi-Automatic / PLC |

| CO₂ Flow Rate | 10–25 kg/h |

| Power Supply | 380V / 50Hz / 3-Phase |

Typical Applications

- Essential Oil Extraction: Lavender, rosemary, citrus peels, sandalwood

- CBD & Hemp Extraction: Full-spectrum oil, terpene-rich extracts, wax removal

- Natural Skincare Ingredients: Oils for lotions, balms, and massage oils

- Functional Foods & Nutraceuticals: Curcumin, lycopene, ginseng, grape seed oil

- Botanical Active Compounds: Flavonoids, carotenoids, alkaloids

CO2 Extraction Workflow

- Raw material loading into the 50L extraction vessels

- CO2 pressurization and heating to the supercritical state

- Supercritical CO2 passes through the material bed to dissolve target compounds

- Multi-stage separation to recover oils, waxes, and volatiles

- CO2 recovery and circulation for the next cycle

This closed-loop process ensures efficient use of CO2 with minimal loss.

FAQ – Frequently Asked Questions

Q1: How much material can be processed per batch?

A1: Depending on bulk density and packing, each batch typically handles 10–20 kg of raw material.

Q2: Is the system suitable for CBD oil extraction?

A2: Yes. It supports full-spectrum cannabinoid extraction, terpene retention, and dewaxing, with optional short-path distillation.

Q3: What is the extraction cycle time?

A3: Each batch usually takes 2–4 hours, depending on the plant type and parameter settings.

Q4: Is this machine GMP compliant and export-ready?

A4: Absolutely. The system meets CE/GMP standards and includes technical documents and overseas installation support.

Optional Configuration

- PLC control with touchscreen panel

- CO2 recovery and purification system

- Multi-stage separation + rectification column

- Vacuum dryer for raw material pretreatment

- Jacketed vessels with precise temperature regulation

Why Choose Us?

- ✅ OEM/ODM customization available

- ✅ Extensive export experience to the US, EU, Southeast Asia, and the Middle East

- ✅ Fully GMP-certified workshops and CE-approved systems

- ✅ Professional overseas support, remote debugging, and pilot testing service

Trusted by Global Clients

Our CO2 extraction systems have been sold to over 30 countries, including the USA, Germany, Thailand, and Australia. From start-up brands to well-known herbal extract manufacturers, our customers trust us for:

- Reliable equipment performance

- Excellent technical support

- One-stop turnkey solutions

- Remote installation guidance and training

Supercritical CO2 Extraction Market Report

Contact Us

Looking for the right supercritical CO2 extraction equipment for your business? Contact us today for custom quotes, technical consultation, and free extraction process evaluation.

Email: [email protected]

WhatsApp/Phone: +86-134-8515-5519

You can view other models of supercritical CO2 extraction equipment [View More]