CO2 Essential Oil Extraction Equipment

Supercritical CO2 Extraction Solutions — From R&D to Industrial Production

Delivering High-Purity, Sustainable Extraction Systems for Natural Oils, Botanicals & Specialty Ingredients

What is

supercritical CO2 extraction machine?

Supercritical CO2 fluid extraction (SCFE) is an advanced separation technology that utilizes supercritical fluid as the extraction solvent.

The Four Major Advantages of Supercritical CO2 fluid

Supercritical CO2 fluid boasts numerous advantages over traditional solvents, making it the preferred choice for various applications. Some key benefits include:

- Selective Extraction: Supercritical CO2 fluid extraction allows for the selective extraction of target compounds by adjusting pressure and temperature parameters.

- Safety and Environmental Friendliness: CO2 is non-toxic, non-flammable, and readily available, eliminating the need for hazardous organic solvents.

- Mild Processing Conditions: The low operating temperatures and pressures of supercritical CO2 fluid minimize the risk of thermal degradation and preserve the quality of the extracted compounds.

- Versatility: Supercritical CO2 fluid can extract various compounds, including essential oils, flavors, fragrances, pharmaceuticals, and natural products.

Classification of

Supercritical CO2 Extraction Machine

Based on customer requirements, we can provide highly competitive design, production, and sales services, ranging from 4-ounce benchtop CO2 extractors to 1-pound small-scale CO2 extractors, and up to 3000-pound industrial CBD oil CO2 extractors and CO2 essential oil extraction equipment.

- Tabletop CO2 Extractor: Extraction capacity ranges from a few milliliters to 200 milliliters. Primarily used for small-scale CO2 extraction experiments. [Read More]

- Small CO2 extraction machine: Extraction capacity ranges from 200 to 5,000 milliliters. Equipped with dual extraction vessels or a supercritical CO2 fractionation column in special cases. Used for scaling up CO2 extraction processes. [Read More]

- Pilot-scale Supercritical CO2 Extractors: Designed for process scale-up and optimization, these systems feature an extraction capacity ranging from 5,000 to 50,000 milliliters. Typically equipped with dual extraction vessels, and optionally with a supercritical CO2 fractionation column for advanced separation needs. Ideal for bridging the gap between laboratory trials and industrial production. [Read More]

- Industrial CO2 Extraction Machine: Extraction capacity ranges from 50 liters to 9,000 liters. Available in two structural types: frame-type and platform-type. Frame-Type: Extraction vessels with capacities below 100 liters, or dual vessels of 100 liters and 150 liters in special cases. Platform-Type: Combines three 100-liter or 150-liter extraction vessels with a larger vessel exceeding 150 liters. [Read More]

Read More: CO2 Extraction Machine: 3 Types

Over 30 years of design and production of supercritical CO2 extraction equipment

Efficient and convenient essential oil supercritical CO2 extraction equipment

BIT supercritical CO2 extraction serves dozens of national laboratories and enterprises around the world

Advantages of

Supercritical CO2 Extraction Machine

In the supercritical phase, CO2 exhibits unique properties that combine gas-like diffusivity with liquid-like density, making it an ideal solvent for extracting essential oils, flavors, fragrances, and bioactive compounds from natural products.

- Efficient Separation: Supercritical extraction combines extraction and separation, improving efficiency through pressure reduction or temperature variation.

- Pressure and Temperature Control: Pressure and temperature are precisely adjusted based on material and compound characteristics, ensuring efficiency and quality.

- Safety Protection: Equipped with overpressure protection gauges and valves to prevent damage.

- User-Friendly Interface: An intuitive interface and flowchart are used for easy operation and understanding.

- Wide Applicability: Supercritical extraction is widely used in natural products, food, fragrance, and pharmaceutical industries.

Applications of

Supercritical CO2 Extraction Machine

The BIT supercritical carbon dioxide extraction machine, with its environmental friendliness and high efficiency, has demonstrated broad application prospects in multiple industries, especially in the essential oil extraction sector.

- Food Industry: Decaffeination of coffee/tea; extraction of natural flavors, spices, and plant oils.

- Pharmaceutical and Cosmetics: Efficient extraction of active pharmaceutical ingredients (e.g., artemisinin), natural antioxidants, and plant essential oils.

- Environmental Protection: Removal of pollutants from soil and water (pesticides, polycyclic aromatic hydrocarbons), and treatment of industrial waste.

- Chemical Industry and Energy: Polymer purification, catalyst regeneration; extraction of biodiesel raw materials (microalgae oil).

- Tobacco: Reduction of nicotine content and extraction of tobacco flavor components.

The working principle of

Supercritical CO2 Extraction machine

The main components of the supercritical carbon dioxide extraction machine work in synergy to ensure that the supercritical carbon dioxide extraction equipment operates safely, stably, and efficiently under high-pressure and high-temperature conditions.

- Dry the biomass to a moisture content of less than 10%.

- Grind the biomass to a particle size of 40-60 mesh.

- Load the biomass into the extraction basket and place it into the extraction vessel.

- Start the CO2 extraction machine and introduce CO2 gas into the extraction vessel to form a supercritical CO2 fluid.

- Adjust the pressure, temperature, and CO2 flow rate inside the extraction vessel to meet the requirements of the biomass extraction target.

- Adjust the pressure and temperature of the separation vessel group according to the extraction target, causing the CO2 fluid to lose its supercritical state and turn into a liquid. This allows the CO2 extract to be separated from the gas, yielding different CO2 extracts (heavy and light components).

- Direct the CO2 liquid into the gas intermediate storage tank in a closed-loop manner.

- The CO2 liquid flows from the gas storage tank and intermediate storage tank, passes through a filter, and re-forms into supercritical CO2 fluid for the next cycle.

- After the specified run time, depressurize the system by releasing CO2 through separator 1 or 2 to obtain the CO2 extract.

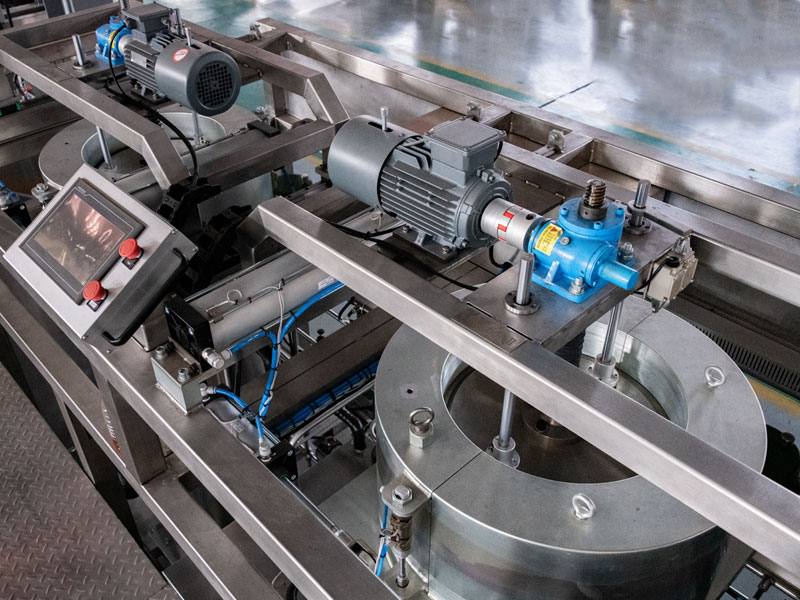

Main Components of

Supercritical CO2 Extraction machine

BIT’s supercritical CO2 extractors are fully customized systems, including co-solvent systems and touchscreen control systems, providing optimized solutions for each customer’s extraction targets and processes

- Extraction System: Typically consists of single or multiple extraction vessels, with 2 to 3 extraction vessels being the standard configuration (up to 6 can be configured).

- Separation System: Typically consists of single or multiple separation vessels. Popular CO2 extraction machines usually have 2 to 3 extraction vessels and 3 separators.

- Supercritical Fluid Generation and Closed-Loop Operation System: This system, made up of a CO2 high-pressure pump, filters, mixers, and fluid transmission lines, generates supercritical CO2 fluid. The CO2 pump pressurizes the high-pressure liquid into the supercritical fluid state, which then dissolves and extracts targets from biomass. The extracted substances are separated via depressurization and returned to liquid form for recirculation.

- Heat Exchange System: Responsible for providing the necessary energy to regulate the temperatures of the extraction and separation vessels.

- Control System: A CNC control system for real-time, automatic regulation of the extraction machine’s temperature, pressure, and flow rate.

ABOUT US

Borisbang Industrial Technology Co., Ltd. has been designing and producing supercritical fluid systems for more than 30 years.

BIT’s laboratory, pilot, commercial and industrial supercritical CO2 extraction machines are sold worldwide. China’s market share exceeds 80%. Exports to the United States, Canada, Argentina, the United Kingdom, Italy, Switzerland, France, Poland, Spain, Hungary, New Zealand, India, South Korea, North Korea, Taiwan, Sri Lanka, Morocco and other countries.

WHY BIT DELIVERS THE BEST CO2 EXTRACTION SOLUTIONS

BIT has specialized in supercritical CO2 extraction technology for over 30 years. With extensive engineering expertise, advanced equipment manufacturing capability, and proven applications across multiple industries, we provide global customers with efficient, safe, and fully customized CO2 extraction solutions.

One-Stop Customized Solutions

From raw material evaluation → process design → equipment manufacturing → installation & commissioning → operator training → after-sales service, we cover the entire process, saving clients time and effort.

Precise Engineering Design

Our professional engineering team tailors system parameters according to plant type, production capacity, and application requirements, ensuring every system delivers high yield with low energy consumption.

High-Standard Manufacturing & Certification

All equipment is built with food-grade 304/316 stainless steel and certified to GMP, CE, ISO, ASME, and other international standards—meeting the strict demands of food, flavors & fragrances, pharmaceuticals, and cannabis extraction.

Extensive Multi-Industry Experience

BIT extraction systems are widely applied in essential oils, flavors, herbal medicine, bioactive compounds, CBD, cannabinoids, natural pigments, and more. We have a proven track record with international clients across diverse industries.

Technical Support & After-Sales Service

We provide global remote support, on-site installation, operator training, process optimization, and lifetime technical service. This ensures long-term stable operation of your equipment and consistently high-quality essential oils or extracts.

FAQ

Application of CO2 Extraction in Essential Oils

Supercritical CO2 extraction offers significant advantages in essential oil production. Unlike traditional steam distillation or solvent extraction, it operates at low temperatures, preventing the degradation of heat-sensitive compounds such as aromatic molecules, monoterpenes, and sesquiterpenes. This ensures maximum retention of the plant’s original aroma and bioactive components.

Why CO2 Extraction Is the Ideal Choice for Essential Oils

Supercritical CO2 extraction is a green, efficient, and gentle method for producing essential oils. Compared with steam distillation and organic solvent extraction, it offers the following benefits:

- Low-Temperature Operation – Protects Active Compounds

- Operates close to room temperature, preserving heat-sensitive constituents like aromatic esters, terpenes, and flavonoids, and preventing thermal degradation or oxidation.

- No Residue – Pure and Safe

- After extraction, CO2 naturally evaporates without leaving harmful solvent residues, making it suitable for pharmaceutical, food-grade, and cosmetic-grade essential oils.

- High Selectivity and Efficiency

- Temperature and pressure can be precisely adjusted to target specific aromatic fractions or essential oils, allowing for fractionated extraction.

- Eco-Friendly and Sustainable

- CO2 can be recycled during the process, producing no pollution or harmful emissions, in line with green manufacturing principles.

NEWS & EVENTS

-

Supercritical CO2 Extraction of Spice Essential Oils

Spice essential oils are natural aromatic oils obtained from spices such as seeds, fruits, flowers, roots, and bark. They are widely used in everyday products, including foods, seasonings, beverages, pharmaceuticals, and fragrances. The quality of spice essential oils largely depends on how gently and efficiently they are extracted, especially when the aroma compounds are sensitive […]

-

High-Quality Pumpkin Seed Oil Production via Supercritical CO2 Technology

1. Advanced Fluid Technology for Botanical Research Supercritical CO2 (SC-CO2) extraction is the gold standard for researching heat-sensitive lipid compounds. For laboratories focusing on functional oils, the ability to precisely control the fluid state is paramount. This study utilizes pumpkin seed oil—a complex matrix rich in PUFAs (76%+), Tocopherols, and Phylloquinone—to demonstrate the precision and […]

-

Supercritical CO2 Extraction of β-Carotene from Sweet Potato

Introduction to β-Carotene Extraction β-Carotene is a natural pigment widely found in plants. It is approved as a food additive. It is also known for its antioxidant activity. Therefore, it attracts strong interest in the food and health industries.However, traditional extraction relies on organic solvents. This causes solvent residue. It may also damage pigment quality. […]