1. Overview of BIT I-150D (150L×2) Supercritical CO₂ Extraction System

The BIT I-150D (150L×2) supercritical CO₂ extraction equipment is a high-efficiency industrial extraction system. It features two extraction vessels and three separation vessels and uses advanced supercritical CO₂ extraction technology. By applying temperatures above 31°C and pressures exceeding 7.38 MPa, CO₂ enters a supercritical state, achieving high solubility and zero surface tension. This allows for precise, efficient extraction of bioactive compounds from plants.

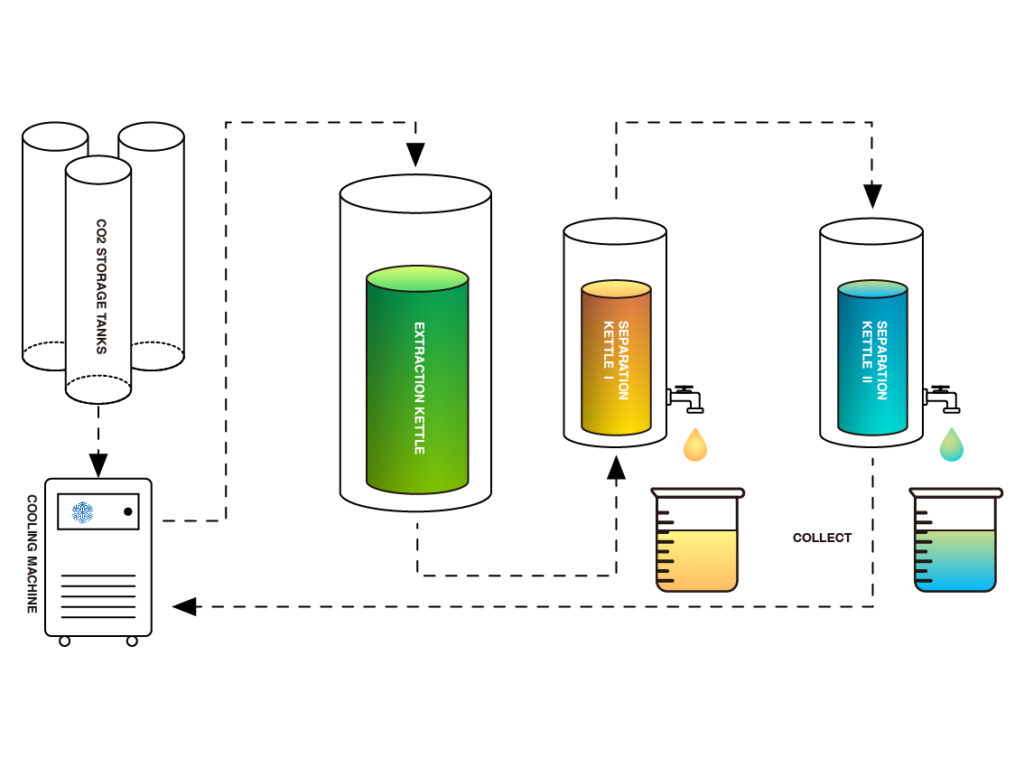

1.1 How It Works

During extraction, the system precisely regulates pressure and temperature, ensuring optimal dissolution of target compounds. The CO₂-extract mixture enters the separation vessel, where pressure reduction or temperature increase causes the extracted compounds to precipitate. A closed-loop CO₂ recovery system reduces CO₂ consumption and operational costs.

1.2 Key Features

- Optimized from the 50L×6 model, offering simpler operation and shorter extraction time.

- Dual extraction vessels operate alternately, ensuring continuous high-efficiency production.

- User-friendly interface with an intuitive process flow diagram, making operation and training easy.

- Pre-assembled design for simplified on-site installation.

- Customizable versions are available to meet specific production needs.

2. Advantages of the I-150D (150L×2) Supercritical CO₂ Extraction Equipment

2.1. Low Critical Temperature

This system is perfect for extracting heat-sensitive compounds, such as essential oils and plant-based pharmaceuticals.

2.2. Oxygen-Free Environment

It prevents oxidation, preserving the potency and purity of extracted compounds.

2.3. High Efficiency & Safety

CO₂ extraction is non-toxic, non-flammable, and environmentally friendly, ensuring safe and clean operation.

2.4. No Residual Solvents

The process leaves zero solvent residues, nitrates, or heavy metal ions, making it ideal for pharmaceutical and food applications.

3. Technical Specifications

| Component | Specification |

|---|---|

| Extraction Vessels | 150L (2 vessels), Max Pressure: 35 MPa |

| Separation Vessels | 3 × 20L, Max Pressure: 20 MPa |

| Pumps | High-pressure CO₂ pump & carrier pump |

| Cooling System | Temperature Range: 5°C – 10°C |

| Heat Exchange System | Max Pressure: 30 MPa |

| Purification System | Max Pressure: 16 MPa |

| CO₂ Storage Tank | Max Pressure: 8 MPa |

| Safety Features | Overpressure protection, safety valves in all key components |

| Power Consumption | 110 kW |

| Temperature Control | Ambient – 75°C |

| User Requirements | Installation Space: 6000mm × 4900mm × 6000mm, CO₂: Food-grade 99.9%, Electricity: Three-phase |

4. Why the 300L Supercritical CO₂ Extractor is the Market’s Top Choice for Botanical Extraction

The 300L supercritical CO₂ extraction system has become a best-selling industrial extraction solution due to its perfect balance of capacity, cost-effectiveness, and versatility.

4.1. Optimal Balance Between Capacity and Cost

- Batch Capacity: 80–120 kg per cycle (varies based on material density and target compound content).

- Daily Output: Up to 500 kg with 24-hour continuous operation.

- Investment Efficiency:

- 3× higher capacity than a 100L system.

- Only 1.8× higher cost, making it cost-effective for mid-scale commercial production.

- Fast ROI, ideal for CBD extraction, essential oils, food additives, and pharmaceutical applications.

4.2. Versatile Applications

- Ideal for high-end products like pharmaceutical and nutraceutical extracts.

- Perfect for mass-market applications, such as food flavors, fragrances, and cosmetics.

4.3. Advanced Process Control

- Siemens PLC control system with 30 pre-set botanical extraction templates (e.g., CBD, ginkgo flavonoids).

- Real-time monitoring of CO₂ density (adjustable between 0.2–0.9 g/cm³), enhancing selectivity by 40%.

4.4. Modular Expansion Design

- Multiple systems can be connected to scale up production to 1,000L+ capacity.

- Compatible with inline chromatography, enabling direct 90% purity compound extraction.

4.5. Regulatory Compliance

- CE/PED/ASME-certified, fully GMP-compliant for pharmaceutical and food industries.

- Solvent residue <1 ppm, meeting FDA 21 CFR and EU Novel Food regulations.

5. What is Supercritical CO₂ Extraction? – Solvent-Free, High-Purity Botanical Extraction

Supercritical CO₂ extraction is a safe, clean, and highly efficient method for botanical and pharmaceutical extraction. It is an alternative to chemical solvents like butane and ethanol, ensuring higher purity and zero solvent residue.

When CO₂ reaches its supercritical state (above 31°C and 7.38 MPa), it behaves as both a gas and a liquid. This unique property allows for efficient compound extraction without the toxicity or flammability risks associated with conventional solvents.

6. Core Advantages of Supercritical CO₂ Extraction – High Purity, Solvent-Free, and Eco-Friendly

Unlike chemical solvent-based methods, supercritical CO₂ extraction leaves no harmful residues and allows for precise compound targeting.

- Zero Solvent Residue – CO₂ fully evaporates, ensuring pure and safe final products.

- High Selectivity – Pressure and temperature adjustments allow for targeted extraction of CBD, terpenes, or essential oils.

- Eco-Friendly & Safe – CO₂ is non-flammable, non-toxic, and renewable, eliminating the need for complex safety infrastructure.

7. How Supercritical CO₂ Extraction Works – A Step-by-Step Guide

7.1. Raw Material Preparation

• Biomass is ground into fine powder (~100 microns) to increase surface area and improve extraction efficiency.

7.2. Loading the Extraction Vessel

• The pre-treated material is packed into a high-pressure extraction chamber.

7.3. Temperature & Pressure Control

• The system optimizes CO₂ conditions to enter the supercritical phase, ensuring precise compound separation.

7.4. Compound Separation & Collection

• The CO₂-extract mixture enters the separator, where pressure reduction causes CO₂ to revert to gas.

• The pure extracted oil collects in the collection vessel.

7.5. Post-Processing (Optional)

• Depending on requirements, filtration or winterization may be applied to remove waxes and lipids.

• Due to high selectivity, CO₂ extraction typically requires less post-processing than other methods.

8. Applications of Supercritical CO₂ Extraction

Supercritical CO₂ extraction is widely used across multiple industries due to its high precision, efficiency, and solvent-free nature.

- CBD & Hemp Industry – Extracts CBD, THC, and terpenes.

- Pharmaceuticals – Produces active pharmaceutical ingredients (APIs).

- Food & Beverages – Extracts essential oils, flavors, and caffeine.

- Cosmetics & Perfumes – Obtains natural fragrance oils and skincare compounds.

- Nutraceuticals – Extracts omega-3, carotenoids, and curcumin.

With clean, efficient, and scalable extraction capabilities, supercritical CO₂ technology is revolutionizing natural product extraction worldwide.