In the era of green manufacturing and high-value natural product development, traditional chemical extraction and separation processes are significantly transforming toward eco-friendliness, efficiency, and intelligence. Supercritical carbon dioxide (CO2) extraction and reverse osmosis (RO) membrane separation have emerged as two powerful green technologies. Their integrated application across various industries is creating innovative solutions for combined extraction and purification processes.

Overview of Supercritical CO2 Extraction Technology

Supercritical CO2 extraction is a physical extraction technique that utilizes CO2 in its supercritical state to selectively dissolve and separate target compounds. When CO2 is pressurized above 7.38 MPa and heated above 31.1°C, it becomes supercritical, exhibiting both a liquid’s solvating power and a gas’s diffusion ability. This state allows it to penetrate plant tissues and efficiently dissolve lipophilic, volatile, and bioactive compounds.

Key Advantages

- Solvent-free and residue-free: Since CO2 is a gas under ambient conditions, it can be completely released and recycled after extraction, leaving no harmful solvent residues—ideal for food, pharmaceutical, and cosmetic applications.

- Low-temperature operation: Typically conducted between 35–55°C, this method protects heat-sensitive compounds such as polyphenols, vitamins, and flavonoids.

- Highly selective extraction: By adjusting parameters such as pressure, temperature, and flow rate, manufacturers can target specific compounds and even perform multi-stage separations.

- Sustainable and recyclable: The use of recyclable CO2 dramatically reduces both raw material costs and carbon emissions.

Introduction to Reverse Osmosis (RO) Membrane Technology

Reverse osmosis is a pressure-driven separation process based on selective semi-permeable membranes. It plays a vital role in modern purification engineering. By applying pressure greater than the osmotic pressure, water molecules are forced through the membrane while most dissolved salts, organic compounds, colloids, and microbes are effectively retained.

Technical Features

• High-efficiency impurity removal: RO membranes excel at removing water, salts, and small molecular impurities, making them perfect for post-extraction purification and concentration.

• Energy-saving and cost-effective: Compared to thermal concentration, RO membranes operate at lower temperatures and consume less energy, supporting automated and continuous processing.

• Versatile membrane options: Depending on molecular weight, pH, and processing temperature, operators can choose from various materials like polyamide or PES membranes to ensure optimal performance.

• Preservation of bioactivity: The low-temperature nature of RO processing helps preserve sensitive compounds such as enzymes, peptides, and essential oils.

Synergistic Integration of Both Technologies

Process Flow Design

Supercritical CO2 Extraction → Separation and Condensation → RO Membrane Purification/Concentration → (Optional) Drying → Product Packaging

In industrial applications, supercritical CO2 efficiently extracts valuable substances such as essential oils, pharmaceuticals, and functional lipids. However, the initial extract often contains residual moisture and unwanted byproducts. Integrating a reverse osmosis unit allows for:

- Effective dehydration

- Removal of small-molecule impurities and salts

- Molecular-level fractionation and concentration

- Reduced drying energy consumption and improved overall efficiency

Application Case Studies

• Extraction and Purification of Plant Essential Oils

After extracting essential oils like lavender, rosemary, or sandalwood using supercritical CO2, trace amounts of water and non-volatile impurities may remain. RO membranes can purify these extracts without damaging aromatic compounds, enhancing scent intensity and stability for use in high-end fragrances, skincare oils, or aromatherapy products.

• Separation of Natural Medicinal Compounds

Catechins from green tea, proanthocyanidins from grape seeds, and flavonoids from ginkgo leaves can be efficiently extracted using supercritical CO2. Subsequent RO membrane purification improves purity and consistency, laying a solid foundation for pharmaceutical formulation and bioactivity testing.

• Processing of ω-3 Functional Oils

EPA and DHA, found in fish and algae oils, can be extracted with CO2 and further purified via RO to remove free fatty acids, oxidation products, and unpleasant odors. The result is a more stable and palatable product suitable for infant nutrition or premium dietary supplements.

Advantages of an Integrated System

- Eco-friendly and efficient: The entire process avoids the use of organic solvents, emits no waste liquids or gases, and significantly reduces environmental impact.

- Enhanced product value: High-purity, stable natural compounds meet stringent standards for pharmaceuticals, functional foods, and cosmetics.

- High automation potential: With clear system interfaces, the integrated process supports seamless control and real-time quality monitoring.

- Cost-effective for SMEs: The modular design suits small and medium-sized enterprises, reducing capital investment and operational risk.

Future Development Trends

With the rise of “green manufacturing,” “zero-discharge factories,” and “standardized natural extraction,” the deep integration of supercritical CO2 and membrane technologies is becoming a cornerstone of industrial advancement.

Key Outlooks

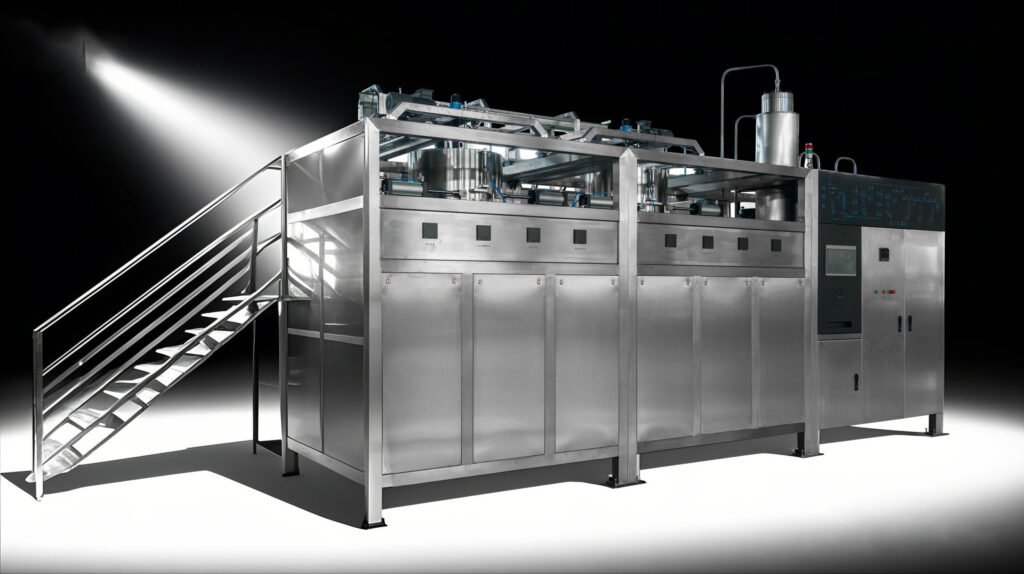

- Modular equipment platforms: Standardized, plug-and-play modules allow for fast deployment, flexible configurations, and low maintenance.

- Smart monitoring systems: AI and IoT platforms enable real-time tracking of critical parameters such as temperature, pressure, flow rate, membrane flux, and product concentration.

- Development of new functional membranes: Research is focusing on organic solvent resistance, anti-fouling performance, and biodegradable materials for processing complex natural extracts.

- Multi-membrane systems: Combining RO with nanofiltration (NF), ultrafiltration (UF), and microfiltration (MF) allows for multi-stage, molecular-level purification.

- Establishing green certification systems: Standardization and certification of integrated extraction processes will increase recognition in both domestic and international markets.

Frequently Asked Questions (FAQ)

What is supercritical CO2 extraction, and why is it considered a green technology?

Supercritical CO2 extraction is a solvent-free method that uses carbon dioxide in its supercritical state to selectively dissolve natural compounds. It avoids toxic organic solvents, operates at low temperatures, and allows for CO2 recycling, making it an environmentally friendly and highly efficient green extraction technology.

How does reverse osmosis membrane technology support purification in natural product extraction?

Reverse osmosis membranes remove water, salts, and small impurities from natural extracts without using heat. This gentle, low-energy method is ideal for concentrating and purifying bioactive compounds without damaging their structure or efficacy.

What are the benefits of combining supercritical CO2 extraction and reverse osmosis membrane separation?

Integrating these two technologies allows for:

- Complete solvent-free extraction and purification,

- Higher product purity and stability,

- Reduced energy consumption during drying,

- Enhanced efficiency in continuous industrial processes.

This synergy offers a comprehensive solution for green extraction and downstream processing.

Which industries benefit the most from this integrated technology?

Industries that gain significant value include:

- Pharmaceuticals, for high-purity plant-based active compounds,

- Functional food and supplements, for clean-label omega-3 oils and antioxidants,

- Cosmetics and perfumery, for essential oils with preserved fragrance and bioactivity,

- Natural health products, for herbal extracts with minimal processing degradation.

Is the integrated system suitable for small and medium-sized enterprises (SMEs)?

Yes, modular and scalable designs allow SMEs to adopt this technology efficiently. The system reduces capital and operational risks while enabling the development of high-value niche products in a cost-effective, eco-conscious way.

Can this integrated process be automated or monitored remotely?

Absolutely. With smart sensors, AI algorithms, and IoT platforms, manufacturers can monitor real-time parameters such as CO2 pressure, membrane flux, and extract concentration. This leads to higher precision, better product consistency, and simplified remote maintenance.