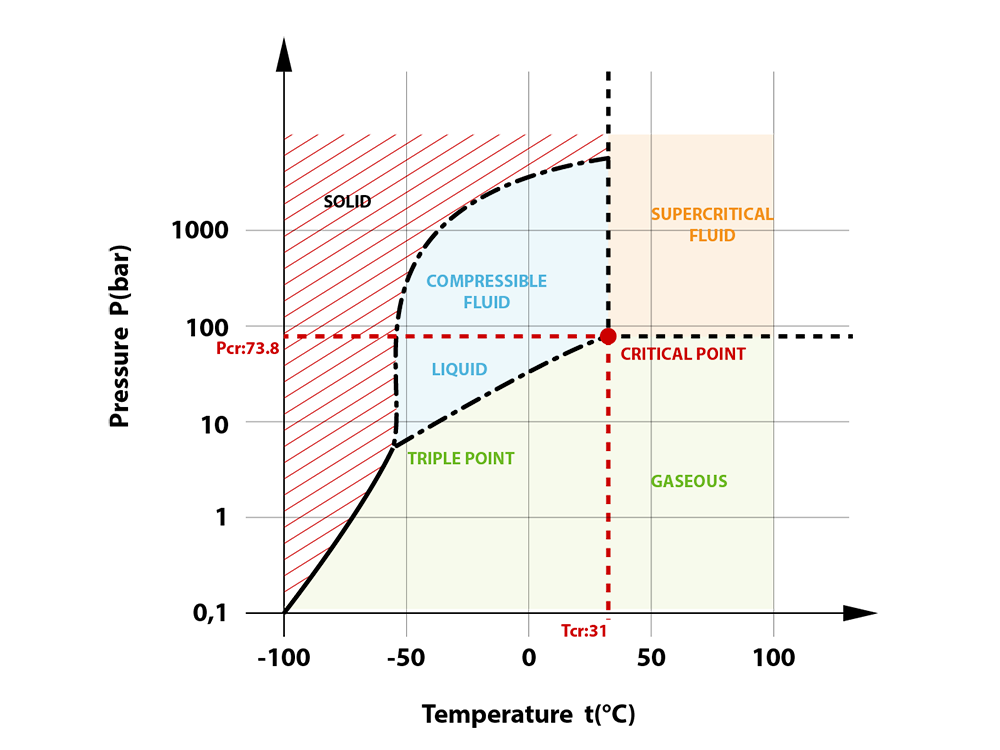

In supercritical CO2 extraction, pressure is the most critical operating parameter that determines the solubility, selectivity, and extraction efficiency of target compounds. When carbon dioxide (CO2) is pressurized above 7.38 MPa (73.8 bar) and heated above 31.1°C, it enters a supercritical state — having both gas-like diffusivity and liquid-like solubility.

Typical Pressure Range in CO2 Extraction Equipment

Depending on the material and desired compounds, the pressure in supercritical CO₂ extraction systems typically ranges between:

- Low pressure (10–20 MPa): Suitable for volatile compounds such as essential oils and terpenes.

- Medium pressure (20–30 MPa): Commonly used for extracting lipophilic compounds like cannabinoids, flavors, and active ingredients.

- High pressure (30–45 MPa): Applied when targeting dense, high-molecular-weight substances, pigments, or waxes.

Industrial CO2 extraction equipment usually operates with variable pressure control, allowing flexible adjustment according to the extraction stage — such as pre-extraction, main extraction, and separation.

Why Pressure Matters

- Extraction Efficiency: Higher pressure increases CO2 density, improving the solvent power and accelerating extraction.

- Selectivity: By controlling pressure and temperature, operators can “tune” CO2 to extract specific components while leaving unwanted materials behind.

- Product Quality: Proper pressure ensures minimal thermal degradation and preserves delicate aroma and active compounds.

Typical Pressure Settings for Different Applications

| Application | Pressure Range (MPa) | Description |

|---|---|---|

| Essential oils (mint, ginger, lavender) | 10–25 | Preserve aroma compounds |

| Cannabinoid extraction (CBD, THC) | 25–35 | High efficiency & purity |

| Pigments and waxes | 30–45 | For dense or viscous materials |

| Food-grade extracts | 15–30 | Safe and mild operation |

Pressure and Separator Design

Modern CO2 extraction systems often include two or three separators operating at decreasing pressures (e.g., 30 MPa → 10 MPa → 5 MPa) to fractionate compounds based on their volatility and polarity. This staged pressure release helps isolate different fractions such as terpenes, cannabinoids, and waxes more precisely.

Conclusion

Pressure control is the heart of any supercritical CO2 extraction process. With precise regulation, operators can balance yield, selectivity, and product quality — making CO2 extraction one of the cleanest and most efficient technologies for natural product processing.

Trusted by Global Clients

Our CO2 extraction systems have been sold to over 30 countries, including the USA, Germany, Thailand, and Australia. From start-up brands to well-known herbal extract manufacturers, our customers trust us for:

- Reliable equipment performance

- Excellent technical support

- One-stop turnkey solutions

- Remote installation guidance and training

Supercritical CO2 Extraction Market Report

Contact Us

Looking for the right supercritical CO2 extraction equipment for your business? Contact us today for custom quotes, technical consultation, and a free extraction process evaluation.

Email: [email protected]

WhatsApp/Phone: +86-134-8515-5519