Supercritical CO2 extraction is widely used in industries such as essential oils, CBD, and botanical extracts due to its efficiency and eco-friendliness. However, solvent recovery in supercritical CO2 extraction systems plays a crucial role in reducing operational costs and environmental impact.

This article covers the feasibility of low-pressure operation, CO2 recycling in extraction, and techniques to optimize solvent recovery, helping buyers make informed decisions when purchasing supercritical CO2 extraction equipment.

How is CO2 used as a solvent? [Read More]

Feasibility of Low-Pressure Operation in Supercritical CO2 Extraction

Supercritical CO2 must maintain a temperature above 31.1°C and pressure above 7.38 MPa to stay in its supercritical state. Operating at low-pressure or near-critical conditions often means CO2 is gaseous or liquid, which lowers density and reduces solubility, significantly impacting extraction efficiency. Such supercritical fluid extraction limitations mean:

- Low-pressure CO2 extraction is only practical for thermally sensitive or non-polar compounds with low solubility requirements.

- High-boiling or polar compounds, commonly found in plant extracts or pharmaceutical industry applications, require true supercritical conditions for effective extraction.

Therefore, for most industrial applications, maintaining proper pressure is essential for a high-yield and efficient supercritical CO2 extraction process.

Optimizing Solvent Recovery in Supercritical CO2 Extraction Systems

Efficient CO2 solvent recovery in supercritical fluid extraction systems not only reduces costs but also minimizes environmental impact. Here are the key methods buyers should consider:

- Pressure Reduction Recovery

After extraction, slowly depressurize the system to convert CO2 from supercritical fluid to gas. This causes solutes to precipitate, allowing gaseous CO2 to be collected and recompressed. This method supports closed-loop CO2 extraction systems and improves CO2 recovery efficiency in extraction systems. - Temperature-Assisted Recovery

By cooling the separator below 31°C, CO2 condenses into a liquid form, facilitating easier storage and recycling. This method is common in supercritical CO2 extraction of essential oils and CBD production, where solvent purity and recycling are critical. - Multi-Stage Separation

Using multiple separators operating at different pressure and temperature gradients improves CO2 solvent recovery methods:- Stage 1 (higher pressure) recovers bulk CO2 and main extracts.

- Stage 2 (lower pressure) captures residual CO2, minimizing solvent loss.

- Compressor Recycling System

Gaseous CO2 is recompressed into the supercritical state and fed back into the extraction cycle, reducing the need for fresh CO2 and lowering operational expenses. Prioritize energy-efficient compressors to maintain a cost-effective system. - Sealing System Optimization

Ensure airtight seals on vessels, pipelines, and valves to prevent leakage. Proper sealing is the foundation for any solvent recovery system and helps maintain system integrity and safety.

Key Considerations for Buyers

- Recovery efficiency depends on temperature, pressure, and CO2 flow rate — optimizing these through testing is essential.

- Impurities in extracts can affect CO2 purity; pre-filtration or separation is recommended.

- Efficient solvent recovery is crucial for reducing costs in industries such as cosmetics, nutraceuticals, and the food industry, where supercritical CO2 extraction of botanical extracts is common.

Summary

Environmental benefits of CO2 recycling in extraction include reduced greenhouse gas emissions and lower solvent waste.

Understanding solvent recovery in supercritical CO2 extraction and related optimization techniques helps buyers choose the right supercritical CO2 extraction equipment for their needs. Implementing pressure and temperature controls, multi-stage separation, and proper sealing ensures high recovery rates, cost savings, and sustainable operations in applications ranging from plant extracts to biofuels.

Further reading: Solvent Recovery in Supercritical CO₂ Extraction – Process Flow

In the supercritical CO₂ extraction process, solvent recovery is a key step that aims to efficiently recover and reuse CO2, reduce costs, and reduce environmental impact. The following is a standard CO2 solvent recovery process, suitable for commercial-grade or experimental/pilot-scale equipment:

1. CO2 Circulation Overview

Supercritical CO2 extraction is a closed-loop system in which CO2 is pressurized and heated to a supercritical state. After the extraction is completed, the solute is precipitated through a separation process, and the CO2 is recovered for the next cycle.

2. Detailed process steps (Step-by-Step Recovery Flow)

- Step 1: Extraction Phase

- The raw materials are placed in the extractor

- CO2 is pressurized to the critical pressure (>7.38 MPa) and heated to the critical temperature (>31.1°C) to become supercritical

- Supercritical CO2 dissolves the target components (essential oils, lipids, fragrances, etc.)

- Step 2: Separation Phase

- CO2-containing solute flows into the separator

- The solute is precipitated and settled by reducing temperature and pressure (multiple separators can be configured for cascade separation)

- The solute is collected at the bottom of the separator

- Step 3: CO2 Phase Transition

- After separation, CO2 is gasified (by reducing pressure or heating)

- Sometimes the residual components are further purified through a gas-liquid separator

- Step 4: Solvent Recovery & Compression (CO2 Recovery and pressurization)

- The separated CO2 enters the recycling tank

- It is then compressed to the working pressure by the compressor or booster pump

- After heating again, it enters the next round of extraction

3. Description of the key steps of solvent recovery:

- Extraction stage: CO2 is mixed with ethanol or other entrainers and enters the extraction kettle to fully contact with the raw materials.

- Multi-stage separation: The separation kettle precipitates the target product (essential oil, extract) step by step according to the temperature and pressure differences, and CO₂ and entrainers continue to flow downstream.

- Condensation recovery:

- CO2 is liquefied after passing through the condenser and enters the CO2 recovery tank, which can be returned to the storage tank for continued use.

- The entrainer (such as ethanol) is recovered by vacuum evaporation or condensation in the distillation unit and sent back to the entrainer storage tank.

- Recovery rate optimization: Set the pressure control valve and condenser temperature control system to ensure the maximum recovery of CO2 and solvent, reduce losses, and operating costs.

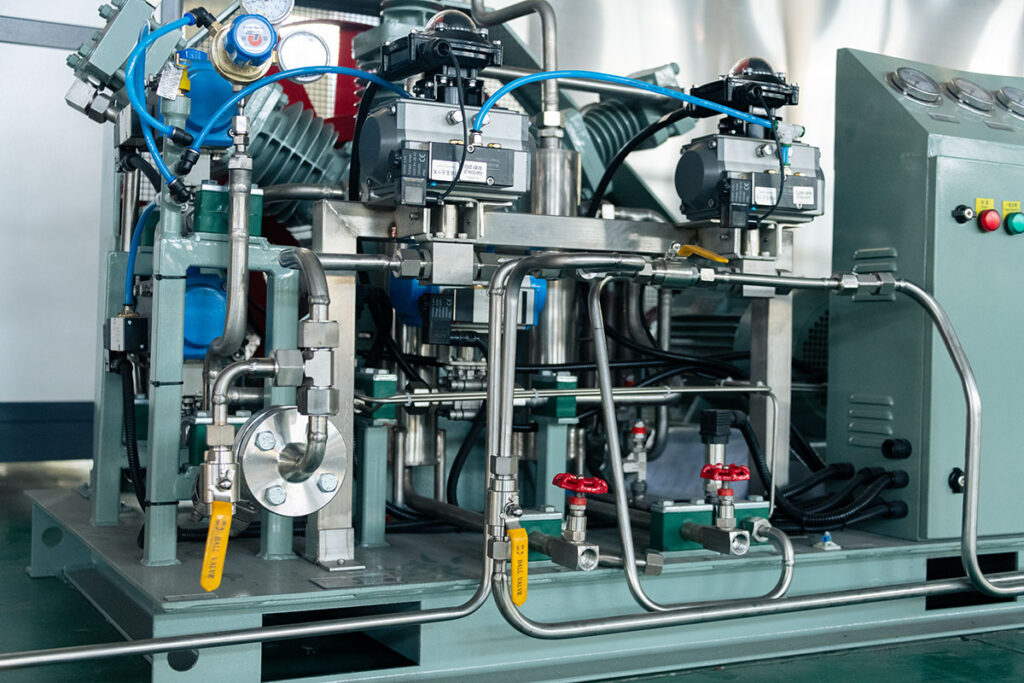

4. Key Equipment in Recovery

| Equipment Name | Functional Description |

|---|---|

| Extractor | Main container for the reaction of CO2 and raw materials |

| Separator | Separates the target product through phase change |

| Recycling Tank | Stores used CO2 for subsequent circulation |

| Compressor/Booster Pump | Restores CO2 pressure to supercritical state |

| Heat Exchanger | Recovers/preheats heat to improve energy efficiency |

| Vent Tank | Collects residual CO2 or gas containing impurities |

| Flowmeter & Control Valve | Controls flow rate and pressure to ensure process stability |

5. Lab vs Industrial

| Project | Small/Experimental | Industrial System |

|---|---|---|

| CO2 Recovery Method | Simplified Pipeline/Small Compressor | High Efficiency Closed Loop + Multi-stage Compression + Energy-saving Heat Exchange |

| Control System | Semi-automatic/Manual Adjustment | Fully Automatic PLC Control |

| Recovery Efficiency | Generally 80–90% | Can reach 95–98% |

| Energy Consumption | Moderate | Energy Management and Cooling System Cooperation Required |

Trusted by Global Clients

Our CO2 extraction systems have been sold to over 30 countries, including the USA, Germany, Thailand, and Australia. From start-up brands to well-known herbal extract manufacturers, our customers trust us for:

- Reliable equipment performance

- Excellent technical support

- One-stop turnkey solutions

- Remote installation guidance and training

Supercritical CO2 Extraction Market Report

Contact Us

Looking for the right supercritical CO2 extraction equipment for your business? Contact us today for custom quotes, technical consultation, and free extraction process evaluation.

Email: [email protected]

WhatsApp/Phone: +86-134-8515-5519

You can view other models of supercritical CO2 extraction equipment [View More]