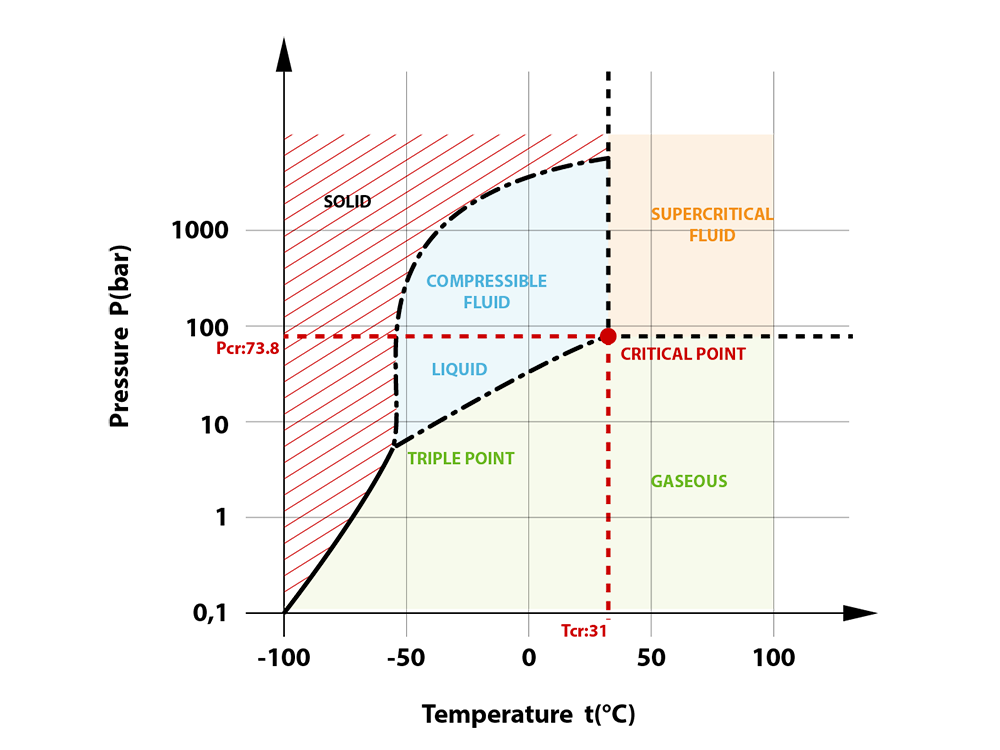

Supercritical CO2 is a unique state of carbon dioxide that forms above 31℃ and 7.38 MPa, combining gas-like diffusivity with liquid-like solubility. This makes Supercritical CO2 highly valuable in chromatography, food processing, chemical production, and environmental protection. In this article, we explore its applications, advantages, challenges, and future prospects.

Need a more detailed understanding of the supercritical CO2 fluid [Read More]

What is Supercritical CO2?

Supercritical CO2 is a phase between gas and liquid with:

- High solubility for organic compounds;

- Eco-friendly properties, non-toxic and non-flammable;

- Mild operating conditions to preserve heat-sensitive compounds.

Supercritical CO2 in Chromatography

Supercritical CO2 is widely used in Supercritical Fluid Chromatography (SFC):

- Reduces organic solvent consumption by over 90%;

- Provides higher separation efficiency;

- Increases the extraction efficiency of natural products by 40% while reducing solvent residues by 80%.

Chemical Industry Applications

In chemical production, Supercritical CO2 accelerates reactions:

- Reaction rates increase 3-5 times with catalysts;

- Product purity rises from 98% to 99.9%;

- Energy savings equivalent to 200 tons of standard coal annually.

Food Industry: Safer Coffee Decaffeination

Supercritical CO2 technology is not only widely used in essential oil and pharmaceutical active ingredient extraction, but also shows great potential in the food industry. It can effectively decaffeinate coffee, improve flavors, and enhance product purity while preserving sensitive nutrients:

- Removes over 98% of caffeine at 35℃ and 15 MPa in two hours;

- Preserves natural coffee aroma and flavor;

- Solvent residue as low as 0.0002%, meeting infant food standards.

This is why an increasing number of food companies are adopting supercritical CO2 as a safe and environmentally friendly processing solution.

According to the U.S. FDA, the safety and broad applications of CO2 in food have already been recognized by authoritative institutions (Food applications of CO2).

Environmental Protection: E-Waste Recycling

Supercritical CO2 plays a key role in sustainable waste management:

- Decomposes epoxy resin in circuit boards;

- Processes 500kg of e-waste per hour;

- Improves heavy metal recovery by 60% and reduces toxic emissions to zero;

- Lowers soil heavy metal levels by 75% in three years.

Challenges in Implementation

- High cost: Supercritical CO2 equipment is 3-8 times more expensive than standard systems;

- Skilled labor shortage: Operators need advanced engineering knowledge;

- Maintenance: High-pressure seals require frequent replacement.

Future Trends and Industrial Growth

- Advanced materials: Graphene coatings extend equipment life 5x;

- Smart control: AI-based systems adjust pressure within 0.1 seconds;

- Industrial clusters: Regions like the Yangtze River Delta are becoming Supercritical CO2 technology hubs, with food industry adoption projected to reach 35% in five years.

Conclusion

Supercritical CO2 is a green, efficient, and versatile technology that is transforming industries from chromatography and food to chemical and environmental sectors. Despite current challenges in cost and operation, ongoing innovations in materials and intelligent systems will ensure that Supercritical CO2 becomes a driving force for sustainable industry in the future.

For detailed specifications and customized solutions, check out CO2 Extraction Machine.

FAQ

1. What is Supercritical CO2?

Supercritical CO2 is carbon dioxide in a state above its critical point, widely used for extraction, separation, and green technologies.

2. What are the advantages of Supercritical CO2 chromatography compared to liquid chromatography?

It reduces solvent use by over 90%, offers higher separation efficiency, and is more eco-friendly.

3. What are the applications of Supercritical CO2 in the food industry?

The most common is coffee decaffeination, which removes caffeine while retaining flavor.

4. How does Supercritical CO2 support environmental protection?

It treats e-waste, recovers heavy metals, and eliminates harmful emissions.

5. What are the main challenges of Supercritical CO2 equipment?

High cost, specialized labor requirements, and frequent maintenance.

6. What is the future of Supercritical CO2 technology?

Advances in materials, AI-based control systems, and industrial scaling will drive growth.

Ready to invest in Supercritical CO2 technology? Contact us today for a customized solution and quotation.

Trusted by Global Clients

Our CO2 extraction systems have been sold to over 30 countries, including the USA, Germany, Thailand, and Australia. From start-up brands to well-known herbal extract manufacturers, our customers trust us for:

- Reliable equipment performance

- Excellent technical support

- One-stop turnkey solutions

- Remote installation guidance and training

Supercritical CO2 Extraction Market Report

Contact Us

Looking for the right supercritical CO2 extraction equipment for your business? Contact us today for custom quotes, technical consultation, and a free extraction process evaluation.

Email: [email protected]

WhatsApp/Phone: +86-134-8515-5519