Supercritical CO2 extraction has become a key technology in the essential oil industry due to its gentle, efficient, and solvent-free nature. Different plant materials, chemical profiles, and product goals determine how the CO2 extraction process flow should be structured. In this article, we’ll explore several typical supercritical CO2 extraction process paths, demonstrating the flexibility and industrial value of this advanced method.

1. Overview of CO2 Extraction Process Combinations

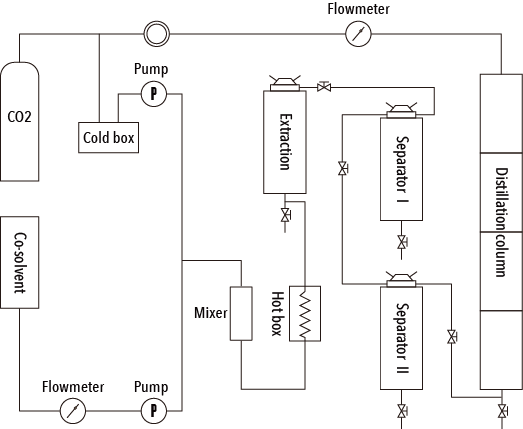

Based on whether a fractionation column is included, the supercritical CO2 extraction system can be structured using the following common flow configurations:

• Standard Extraction Path

CO2 → Extraction Vessel → Separator I → Separator II → CO2 Loop

This is the most basic and widely used setup for extracting essential oils. Separator I typically collects oils and lipids, while Separator II targets waxes or by-products.

• Post-Separation Fractionation

CO2 → Extraction Vessel → Separator I → Separator II → Fractionation Column → CO2 Loop

This route incorporates a distillation column following traditional separation to achieve fine separation of volatile components, thereby enhancing the oil’s purity and sensory profile.

• Pre-Separation Fractionation

CO2 → Extraction Vessel → Fractionation Column → Separator I → Separator II → CO2 Loop

Designed to immediately separate lightweight, aromatic compounds—ideal for extracting floral scents and high-value actives right after extraction.

• Intermediate Fractionation

CO2 → Extraction Vessel → Separator I → Fractionation Column → Separator II → CO2 Loop

This setup is ideal for applications that require mid-process purification of a specific target compound, such as a dominant fragrance or a bioactive compound.

Supercritical CO2 Extraction Basic Process Flow Diagram

In each of these setups, the fractionation column plays a key role in separating light and heavy components, boosting the purity and quality of the final essential oil.

2. Common Extraction System Configurations

Depending on production scale and raw material handling strategy, CO2 extraction systems can be configured modularly as follows:

- 1 Extraction + 1 Separator

- 1 Extraction + 2 Separators

- 1 Extraction + 2 Separators + 1 Fractionation Column

- 2 Extractions + 2 Separators

- 2 Extractions + 2 Separators + 1 Column

- 4 Extractions + 2 Separators

- 4 Extractions + 2 Separators + 1 Column

This modular CO2 extraction system design allows for seamless scaling from laboratory or pilot-level production to full-scale industrial essential oil manufacturing.

3. Choosing the Right Process Path

Each CO2 extraction process flow suits different types of plant materials and essential oil goals:

- Aromatic flowers (e.g., lavender, rose): Benefit from pre- or post-fractionation paths to retain delicate aroma compounds.

- Resinous or wax-rich plants: Require efficient Separator II performance or additional dewaxing modules.

- Complex multi-compound extracts: Perform better with intermediate or post-fractionation for higher separation resolution.

4. Engineering Flexibility & Custom Solutions

As a professional supercritical CO2 extraction equipment manufacturer, BIT offers customized CO2 extraction solutions based on your raw material type and final product goals. Our systems can be configured with fractionation columns, condensers, dewaxing systems, and vacuum cooling modules to build a fully integrated CO2 essential oil production line.

Five Critical Factors When Selecting Equipment [Read More]

Conclusion: The Right Process Determines the Right Value

Choosing the proper supercritical CO2 extraction flow impacts not only the yield and purity of your essential oil, but also its commercial value. Whether you are working with lavender, rosemary, lemongrass, agarwood, or frankincense, BIT can deliver scientifically designed flow combinations and turnkey engineering solutions.

Want to know more about CO2 extraction equipment or successful project cases? Contact us today.

FAQ Section

Q1: What is the advantage of using fractionation columns in CO2 extraction?

A: Fractionation columns enhance the separation of light and heavy compounds, improving the purity and complexity of essential oils.

Q2: Can supercritical CO2 extraction be customized for different plant materials?

A: Yes, the process path can be flexibly designed depending on the material type—whether floral, resinous, or wax-heavy.

Q3: Is the CO2 extraction process scalable?

A: Absolutely. CO2 extraction systems can be configured from 1-extractor setups to 4-extractor industrial-scale units with modular flexibility.

Trusted by Global Clients

Our CO2 extraction systems have been sold to over 30 countries, including the USA, Germany, Thailand, and Australia. From start-up brands to well-known herbal extract manufacturers, our customers trust us for:

- Reliable equipment performance

- Excellent technical support

- One-stop turnkey solutions

- Remote installation guidance and training

Supercritical CO2 Extraction Market Report

Contact Us

Looking for the right supercritical CO2 extraction equipment for your business? Contact us today for custom quotes, technical consultation, and a free extraction process evaluation.

Email: [email protected]

WhatsApp/Phone: +86-134-8515-5519

You can view other models of supercritical CO2 extraction equipment [View More]