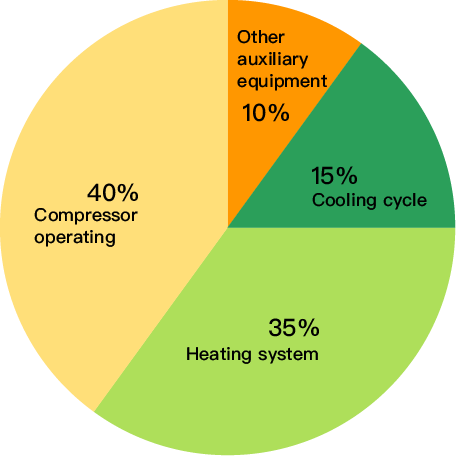

Supercritical CO2 extraction energy consumption is a critical factor in the large-scale industrial application of this advanced and eco-friendly extraction method. While the technology is known for its high efficiency and environmental benefits—operating under relatively low critical temperature and pressure to extract essential oils, bioactive compounds, and natural flavors—the actual production process still requires significant energy input. Understanding the primary energy consumption points is the first step toward reducing operational costs and improving sustainability.

[Additional Information] What is Supercritical CO2 Extraction?

1. Main Energy Consumption Points in Supercritical CO2 Extraction

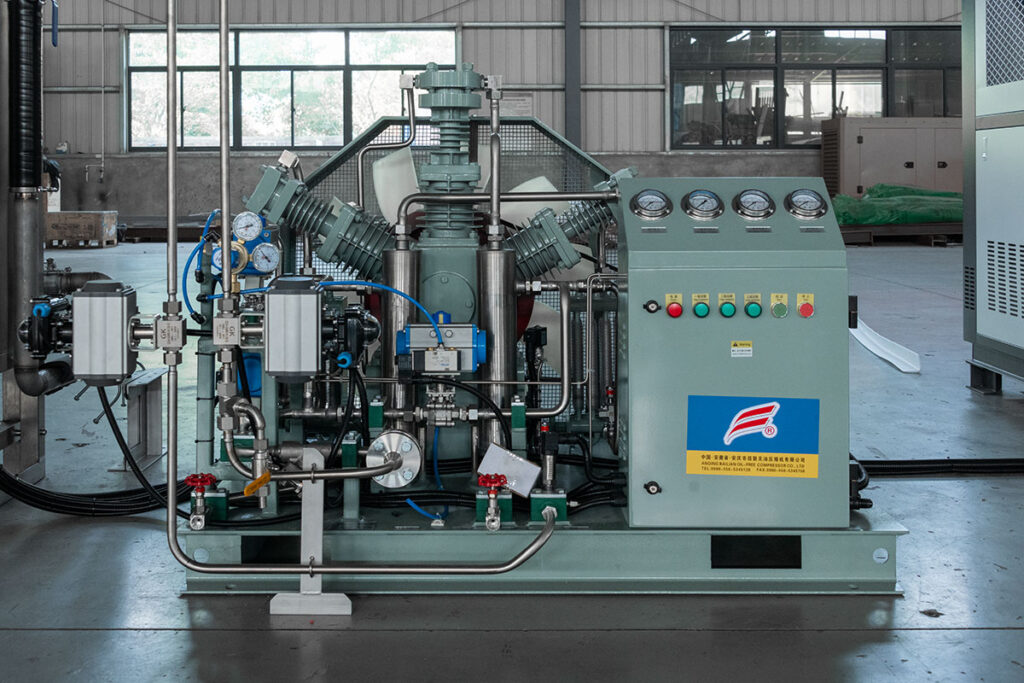

1.1 Compressor Energy Consumption

The compressor is one of the most energy-intensive components in supercritical CO2 extraction systems. To bring CO2 to a supercritical state (critical pressure around 7.38 MPa), the compressor must run continuously and at high power, especially in large-scale, high-pressure operations.

Key factors affecting compressor energy consumption:

- Target extraction pressure

- CO2 flow rate settings

- Compressor efficiency and maintenance quality

1.2 Heating System Energy Consumption

Heating is necessary to raise the CO2 fluid above its critical temperature (31.1°C or higher), with certain materials requiring 50–80°C for optimal extraction. The energy required depends on heating speed, insulation quality, and the heat capacity of the material.

Key factors:

- Target extraction temperature

- Quality of thermal insulation

- Heat recovery efficiency

1.3 Cooling and Circulation Energy Consumption

After extraction, CO2 must be cooled and depressurized for recovery. Cooling units, circulation pumps, and separators all consume energy. Low-efficiency cooling systems increase both energy costs and CO2 loss.

Key factors:

- Heat exchanger efficiency

- Circulation pump power

- System leakage and recovery efficiency

1.4 Process Duration and Auxiliary Equipment Energy Consumption

Batch extraction processes with long operating times increase total energy use. Auxiliary equipment such as control systems, agitators, and sensors also consume electricity throughout the operation.

Key factors:

- Balance between extraction time and yield

- Standby energy consumption

- Automation level and operational mode

2. Strategies to Reduce Supercritical CO2 Extraction Energy Consumption

- Optimize process parameters – Identify the lowest-energy combination of temperature, pressure, and flow rate through experimental analysis.

- Upgrade equipment efficiency – Use high-efficiency compressors and heat exchangers to minimize losses.

- Implement heat recovery – Reuse residual heat from the heating stage to preheat CO2 or raw materials.

- Improve insulation and sealing – Reduce heat loss and CO2 leakage.

- Use intelligent control systems – Automatically adjust parameters to avoid unnecessary full-load operation.

3. Conclusion and Future Trends

The main sources of supercritical CO2 extraction energy consumption are compressors, heating systems, and cooling/circulation systems. With the development of energy-saving compressors, advanced heat exchange materials, heat recovery systems, and smart process control, energy consumption can be significantly reduced. This will expand the technology’s adoption in industries such as food, pharmaceuticals, and essential oils.

FAQ

Q1: Which part of supercritical CO2 extraction consumes the most energy?

A1: The compressor typically consumes the most energy, accounting for more than 40% of total energy use, followed by heating and cooling systems.

Q2: How can compressor energy consumption be reduced?

A2: Lowering target pressure, using high-efficiency compressors, and optimizing run times can significantly cut compressor energy costs.

Q3: How can heating energy consumption be optimized?

A3: Upgrading insulation, implementing heat recovery, and setting reasonable target temperatures can reduce heating costs.

Q4: Can cooling energy be recovered?

A4: Yes, high-efficiency heat exchangers and circulation system designs can reuse cooling energy, minimizing waste.

Trusted by Global Clients

Our CO2 extraction systems have been sold to over 30 countries, including the USA, Germany, Thailand, and Australia. From start-up brands to well-known herbal extract manufacturers, our customers trust us for:

- Reliable equipment performance

- Excellent technical support

- One-stop turnkey solutions

- Remote installation guidance and training

Supercritical CO2 Extraction Market Report

Contact Us

Looking for the right supercritical CO2 extraction equipment for your business? Contact us today for custom quotes, technical consultation, and a free extraction process evaluation.

Email: [email protected]

WhatsApp/Phone: +86-134-8515-5519

You can view other models of supercritical CO2 extraction equipment [View More]