Supercritical CO2 extraction of coffee bean oil is an advanced and eco-friendly method for obtaining high-quality coffee extracts. In this experiment, the process was tested under different pressures and extraction times to evaluate oil yield, aroma quality, and extraction efficiency. The results demonstrate the significant advantages of CO2 extraction technology in producing solvent-free coffee oil suitable for flavor and nutraceutical industries.

1. Objective

To investigate the extraction efficiency and yield of coffee bean oil using a supercritical CO2 extraction system under different pressure and time conditions.

2. Materials and Equipment

- Raw Material: Crushed coffee beans

- Sample Weight: Approximately 500 g

- Equipment: Laboratory-scale Supercritical CO2 Extraction System

- CO2 Purity: ≥ 99.5%

- Temperature: Room temperature (25 ± 2 °C)

- Separator Pressure: 10 MPa

3. Experimental Procedure

Step 1 – Sample Preparation

The coffee beans were crushed into uniform granules to increase the surface area for extraction. The prepared sample weighed approximately 500 grams.

Step 2 – First Extraction

- Extraction Pressure: 20 MPa

- Extraction Time: 25 minutes

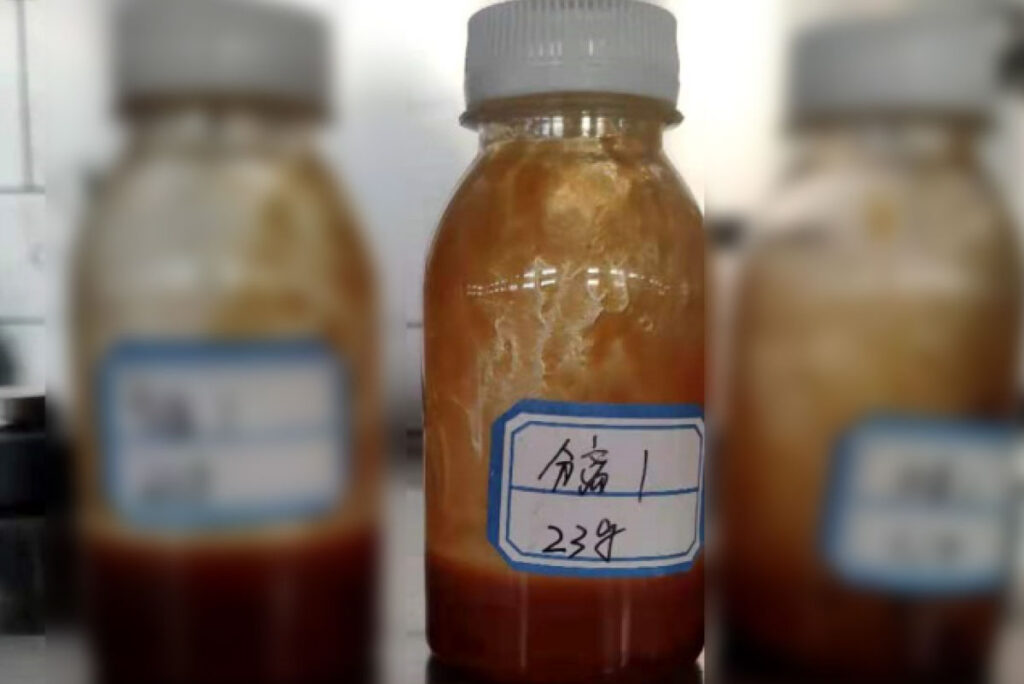

- Result: Obtained 23 g of coffee extract.

This stage primarily extracted volatile aromatic compounds and light oils.

Step 3 – Second Extraction

- Extraction Pressure: 30 MPa

- Extraction Time: 40 minutes

- Result: Obtained 28 g of coffee extract.

At higher pressure, more non-volatile and dense components were extracted.

Step 4 – Separation

- Separator Pressure: 10 MPa

- Extract Collected: 5.3 g

This step facilitated the separation of the extracted oil from CO2, yielding the final concentrated extract.

4、Results Summary

| Item | Description | Extraction Pressure | Extraction Time | Extract Weight (g) |

|---|---|---|---|---|

| 1 | Extraction 1 | 20 MPa | 25 min | 23 |

| 2 | Extraction 2 | 30 MPa | 40 min | 28 |

| 3 | Separator 2 | 10 MPa | — | 5.3 |

| Total Extract | — | — | — | 56.3 |

5. Observations and Notes

- Total extract yield: 56.3 g from 500 g of crushed coffee beans.

- Extraction efficiency: ≈11.26% by weight.

- Extract from the first stage appeared lighter in color and aroma-rich, while the second-stage extract was darker and denser.

- The separated extract (5.3 g) contained concentrated aromatic oil fractions.

6. Conclusion

The supercritical CO2 extraction of coffee beans demonstrated high efficiency in obtaining aromatic oil and essential compounds.

- Optimal extraction occurred at 30 MPa and 40 minutes, producing the highest yield.

- The system achieved clean separation under 10 MPa in the separator, resulting in a total extract yield of 56.3 g.

- This experiment confirms that supercritical CO2 extraction is an effective, solvent-free method for producing high-quality coffee extracts suitable for flavor, fragrance, and nutraceutical applications.

Trusted by Global Clients

Our CO2 extraction systems have been sold to over 30 countries, including the USA, Germany, Thailand, and Australia. From start-up brands to well-known herbal extract manufacturers, our customers trust us for:

- Reliable equipment performance

- Excellent technical support

- One-stop turnkey solutions

- Remote installation guidance and training

Supercritical CO2 Extraction Market Report

Contact Us

Looking for the right supercritical CO2 extraction equipment for your business? Contact us today for custom quotes, technical consultation, and a free extraction process evaluation.

Email: [email protected]

WhatsApp/Phone: +86-134-8515-5519

FAQ

Q1: What is supercritical CO2 extraction, and why is it ideal for coffee oil?

A1: Supercritical CO2 extraction uses carbon dioxide at high pressure and temperature to act as a solvent. It efficiently extracts coffee oil without leaving harmful residues, preserving the natural aroma and flavor compounds.

Q2: What pressure produced the best extraction results for coffee bean oil?

A2: In this experiment, a 30 MPa pressure for 40 minutes achieved the highest extraction yield and captured both volatile and dense aromatic compounds.

Q3: How much coffee oil was obtained in total?

A3: From 500 g of crushed coffee beans, a total of 56.3 g of coffee oil extract was collected, with an efficiency of approximately 11.26%.

Q4: What are the main benefits of using CO2 extraction over traditional solvent methods?

A4: CO2 extraction is solvent-free, safe, and environmentally friendly. It allows precise control of temperature and pressure, preserving delicate aromatic and bioactive compounds.

Q5: Can this technology be scaled for industrial coffee oil production?

A5: Yes. The same principles apply to pilot and industrial-scale CO2 extraction equipment, allowing for consistent, high-quality coffee oil production suitable for flavoring, cosmetics, and nutraceutical industries.