Supercritical CO2 extraction is a safe, solvent-free method for extracting flavors, oils, and bioactives. Ideal for modern, eco-friendly food processing.

1. Introduction: Why Solvent-Free Extraction Matters

Modern food processing needs clean and safe methods. Traditional solvent extraction uses toxic chemicals. These pose health and environmental risks.

Today, supercritical CO2 extraction offers a better way. It is solvent-free, efficient, and eco-friendly. In its supercritical state, CO2 dissolves oils, flavors, and nutrients. It works without harmful solvents.

It also operates at low temperatures. This protects heat-sensitive compounds. As a result, food keeps its natural flavor and nutrition. It’s a perfect match for safe and green production.

2. How Supercritical CO2 Extraction Works

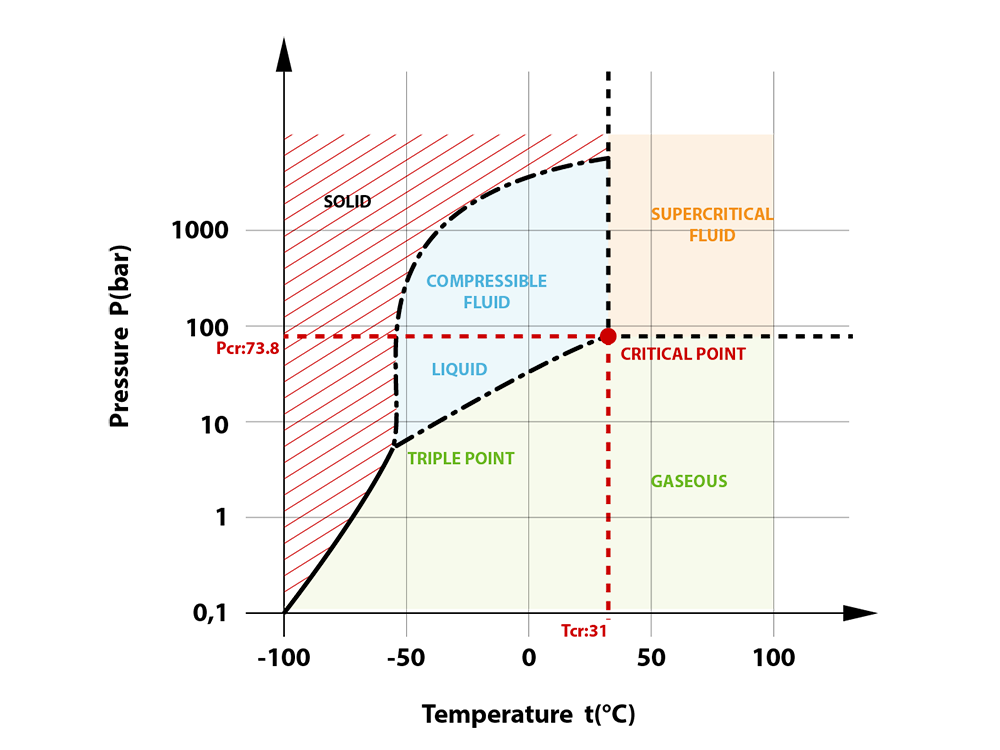

2.1 What Is Supercritical CO2?

CO2 becomes supercritical above 31.1°C and 7.38MPa. In this state, it’s not a gas or a liquid. It has the best of both:

- Spreads fast like a gas

- Dissolves well like a liquid

It enters plant cells and pulls out key compounds. After extraction, reducing the pressure turns CO2 back into gas. No solvent remains in the product.

Supercritical CO2 Extraction: Principles and Industrial Applications of a Green Solvent Technology

2.2 Key Physical and Chemical Actions

The power of CO2 depends on pressure and temperature. These control its density and solubility. You can tune them for each compound.

CO2’s low surface tension helps it pass through cell walls. It reaches deep into the raw material. When pressure drops, the target compounds separate from the CO2.

This makes solvent-free extraction easy and clean.

2.3 Standard Extraction Process

The extraction process follows these steps:

| Step | Task | Equipment | Notes |

|---|---|---|---|

| 1 | Grind raw material | Grinder | CO2 passes through the material |

| 2 | Load material | Extractor | High-pressure vessel |

| 3 | Prepare CO2 | Compressor, heater | Makes CO2 supercritical |

| 4 | Extract compounds | Circulating pump | CO2 passes through material |

| 5 | Separate extracts | Separator | Pressure drop releases compounds |

| 6 | Recycle CO2 | Condenser | CO2 is reused |

| 7 | Collect extracts | Container | Final product gathered |

| 8 | Clean system | Tools | Ensure hygiene and safety |

3. Benefits of Supercritical CO2 Extraction

3.1 High Efficiency

The process is fast. It needs less energy than traditional methods. CO2 penetrates materials quickly and pulls out what’s needed.

Results:

- Shorter processing time

- Higher yields

- Better product quality

3.2 High Safety

CO2 is non-toxic and non-flammable. No explosion risk. No toxic solvent contact. It meets food and pharma safety rules.

It also leaves no residues. Products are pure and clean.

3.3 Environmentally Friendly

CO2 is natural and recyclable. No harmful waste is produced. The system uses a closed loop. This makes it ideal for green manufacturing.

4. Food Industry Applications

4.1 Flavors and Fragrances

CO2 extracts delicate oils and aroma compounds at low heat. It protects flavor quality. Used for:

•Vanilla

•Citrus oil

•Cinnamon

Products are clean and free of solvent traces.

4.2 Oils and Fatty Acids

CO2 works well on plant and animal oils. It keeps oils stable and nutritious. Common uses:

- Sunflower oil

- Soybean oil

- Omega-3 from fish

It also separates key fatty acids for supplements.

[Learn more] Best Capsicum Oleoresin Extraction: Solvent, CO2 Extraction, or Hybrid?

4.3 Bioactive Compounds

CO2 extracts antioxidants, flavonoids, and vitamins. You can adjust pressure and temperature to target each compound.

Benefits:

- High purity

- Active form preserved

- No damage from heat or solvents

5. Conclusion

Supercritical CO2 extraction is fast, safe, and sustainable. It delivers clean, solvent-free food ingredients.

As green tech demand grows, this method becomes more valuable. It’s already used for flavors, oils, and health ingredients.

Future goals include:

- Reducing cost

- Scaling up systems

- Expanding to more products

It’s a smart choice for companies focused on quality, safety, and the environment.

FAQ: Supercritical CO2 Extraction

Q1: What is supercritical CO2 extraction?

A: It uses CO2 under high pressure and temperature to extract compounds without solvents.

Q2: Why is it solvent-free?

A: CO2 turns back to gas after use. No chemical residue remains.

Q3: Is it safe for food?

A: Yes. It’s non-toxic, approved for food and pharmaceutical use.

Q4: What products use this method?

A: Oils, flavors, fragrances, and bioactive nutrients.

Q5: Can CO2 be reused?

A: Yes. The system recycles it in a closed loop.

Trusted by Global Clients

Our CO2 extraction systems have been sold to over 30 countries, including the USA, Germany, Thailand, and Australia. From start-up brands to well-known herbal extract manufacturers, our customers trust us for:

- Reliable equipment performance

- Excellent technical support

- One-stop turnkey solutions

- Remote installation guidance and training

Supercritical CO2 Extraction Market Report

Contact Us

Looking for the right supercritical CO2 extraction equipment for your business? Contact us today for custom quotes, technical consultation, and free extraction process evaluation.

Email: [email protected]

WhatsApp/Phone: +86-134-8515-5519

You can view other models of supercritical CO2 extraction equipment [View More]