This article presents a failed case study of agarwood oleoresin extraction using supercritical CO2 technology. Despite using standard extraction parameters, no significant yield of agarwood oil was obtained. Upon evaluation, the raw material was identified as white wood agarwood, which lacks the resin content and fragrance essential for successful extraction. The report analyzes the process, parameters, and reasons behind the failure and provides key recommendations for selecting high-resin agarwood suitable for CO2 extraction.

1. Materials

1.1 Instruments & Equipment

- 30L (2×15L) supercritical CO₂ extraction equipment

- Electronic balance

30L is a pilot supercritical CO2 extraction equipment [Read More]

1.2 Sample & Reagents

- Agarwood powder

- CO2 (purity 99.5%)

2. Method

2.1 First Extraction Process

Agarwood powder (2.46g) was ground to pass through a 10-mesh sieve and loaded into the 15L extractor. The system was set to:

- Pressure: 31.8 MPa

- Temperature: 65°C

After reaching the target temperature, CO2 was pumped into the extractor. Extraction began after pressure stabilized. After 25 minutes, a small amount of yellow, water-like liquid with traces of resin was collected. Continued extraction yielded ~260 ml of a similar substance.

2.2 Second Extraction

Another 2.45g of agarwood was loaded into the second 15L extractor under the same conditions. Final total collected: ~400 ml of yellow aqueous fluid with very little oleoresin.

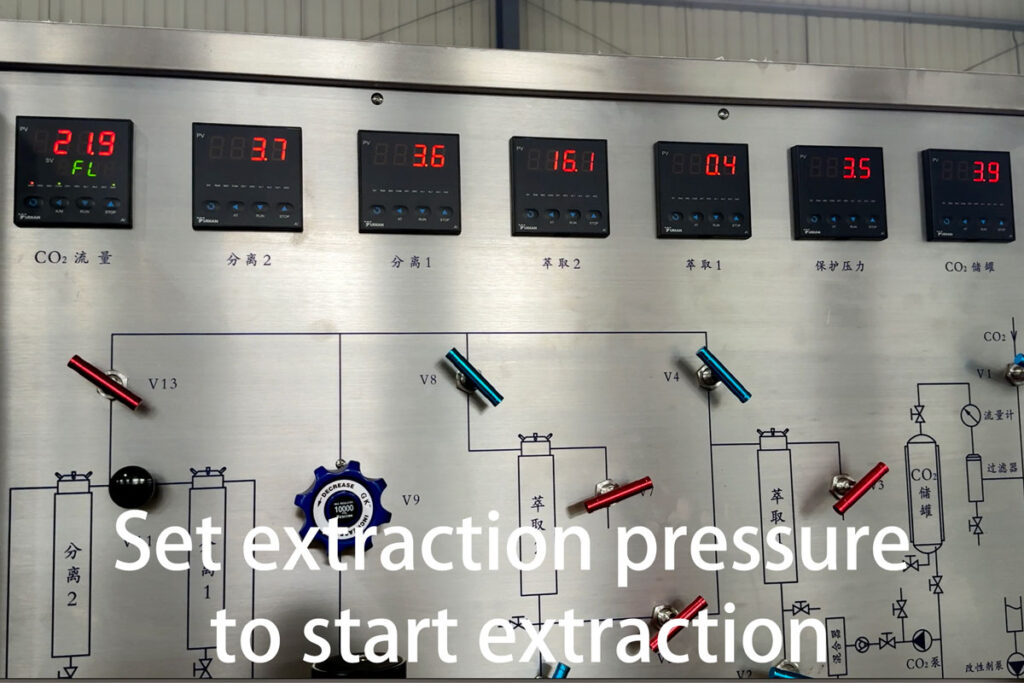

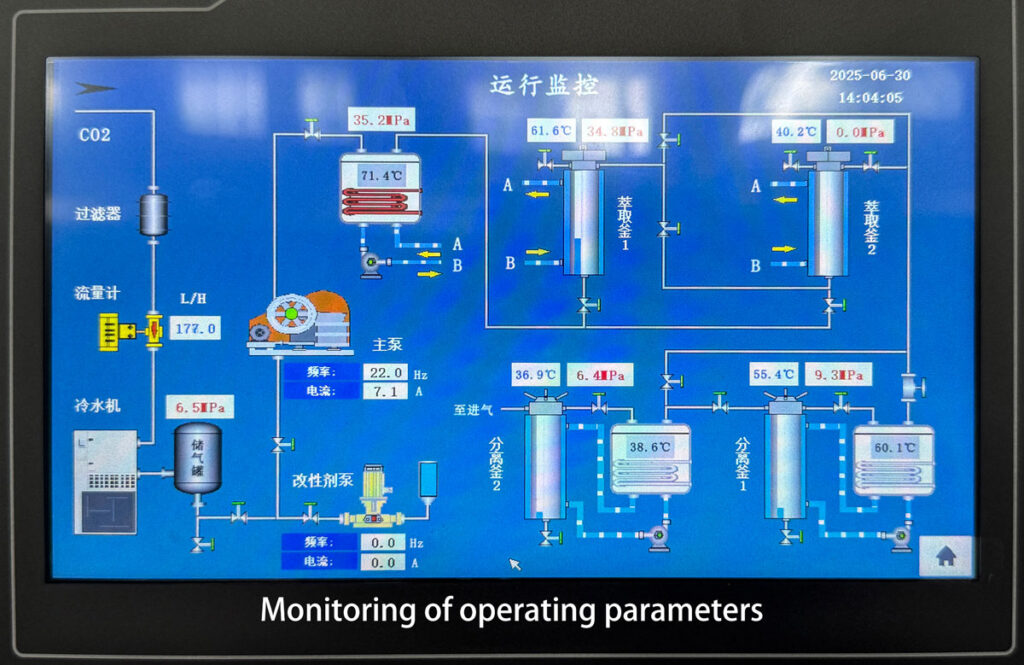

2.3. Extraction Parameters

| No. | Time | Storage Tank Pressure (MPa) | Safety Pressure (MPa) | Extraction 1 Pressure (MPa) | Extraction 2 Pressure (MPa) | Separator 1 Pressure (MPa) | Separator 2 Pressure (MPa) | Flow Rate (L/H) | Extraction 1 Temp (°C) | Separator 1 Temp (°C) | Separator 2 Temp (°C) | Extraction 2 Temp (°C) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 14:55 | 4.50 | 34.50 | 0.00 | 34.40 | 7.10 | 4.40 | 187.30 | 41.00 | 55.10 | 37.40 | 73.40 |

| 2 | 14:50 | 4.50 | 34.50 | 0.00 | 34.20 | 7.10 | 4.50 | 191.00 | 39.20 | 55.00 | 37.70 | 75.60 |

| 3 | 14:45 | 4.60 | 34.50 | 0.00 | 34.30 | 6.90 | 4.60 | 180.10 | 37.00 | 54.80 | 37.60 | 87.40 |

| 4 | 14:40 | 4.70 | 35.10 | 0.40 | 34.60 | 6.30 | 4.70 | 173.60 | 36.50 | 52.00 | 36.20 | 94.00 |

| 5 | 14:35 | 4.40 | 21.00 | 4.80 | 20.70 | 4.50 | 4.30 | 138.40 | 44.00 | 50.00 | 33.00 | 48.20 |

| 6 | 14:30 | 8.00 | 7.50 | 8.20 | 0.20 | 7.90 | 7.80 | 60.40 | 49.50 | 51.60 | 36.70 | 41.00 |

| 7 | 14:25 | 6.60 | 35.30 | 34.80 | 0.00 | 9.50 | 6.50 | 166.10 | 65.80 | 55.40 | 36.00 | 40.80 |

| 8 | 14:20 | 6.50 | 36.30 | 34.80 | 0.00 | 9.50 | 6.40 | 180.00 | 67.50 | 55.40 | 36.00 | 40.60 |

| 9 | 14:15 | 6.50 | 35.30 | 34.90 | 0.00 | 9.50 | 6.40 | 178.00 | 65.00 | 55.40 | 36.30 | 40.50 |

| 10 | 14:10 | 6.50 | 35.20 | 34.80 | 0.00 | 9.40 | 6.40 | 175.20 | 62.70 | 55.40 | 36.60 | 40.30 |

| 11 | 14:05 | 6.50 | 35.20 | 34.80 | 0.00 | 5.30 | 6.40 | 178.40 | 61.50 | 55.40 | 36.80 | 40.20 |

| 12 | 14:00 | 6.40 | 35.20 | 34.80 | 0.00 | 9.20 | 6.30 | 173.20 | 62.10 | 55.40 | 37.00 | 40.10 |

| 13 | 13:55 | 6.40 | 35.20 | 34.30 | 0.00 | 9.00 | 6.30 | 179.00 | 61.70 | 55.00 | 36.90 | 40.20 |

| 14 | 13:50 | 6.40 | 31.80 | 31.40 | 0.00 | 9.00 | 6.40 | 179.90 | 60.70 | 55.00 | 36.90 | 40.40 |

| 15 | 13:45 | 6.40 | 31.80 | 31.30 | 0.00 | 8.90 | 6.40 | 180.80 | 60.80 | 55.10 | 36.70 | 40.70 |

| 16 | 13:40 | 6.40 | 31.80 | 31.30 | 0.00 | 8.80 | 6.40 | 181.00 | 61.20 | 55.10 | 36.50 | 41.00 |

| 17 | 13:35 | 6.30 | 31.80 | 31.30 | 0.00 | 8.80 | 6.30 | 181.60 | 61.40 | 55.20 | 36.10 | 41.70 |

| 18 | 13:30 | 6.20 | 31.60 | 31.20 | 0.00 | 8.70 | 6.20 | 187.00 | 61.30 | 55.00 | 35.70 | 42.40 |

| 19 | 13:25 | 6.20 | 31.30 | 30.90 | 0.00 | 8.50 | 6.20 | 178.70 | 67.10 | 55.30 | 35.00 | 43.30 |

| 20 | 13:20 | 6.20 | 31.90 | 31.50 | 0.00 | 7.80 | 6.10 | 162.80 | 86.70 | 54.40 | 33.80 | 43.00 |

| 21 | 13:15 | 4.20 | 22.10 | 21.90 | 3.70 | 3.90 | 4.00 | 164.10 | 86.50 | 54.10 | 33.20 | 43.20 |

3. Result

The extraction failed to yield a significant amount of agarwood oleoresin. No concentrated agarwood oil was obtained. The raw material lacked the typical agarwood scent. Based on its characteristics, it was identified as “white wood”—low in resin and economically non-viable.

4. Recommendations

What is White Agarwood?

- From healthy Aquilaria trees but without resin

- Lacks aroma, no market value

- Not suitable for CO₂ extraction

What is True Agarwood?

- Formed when Aquilaria trees are wounded (by insects, lightning, or cuts)

- Trees secrete resin, which hardens over the years

- Contains aromatic, high-value resin used for oil extraction

Recommended High-Resin Agarwood Sources:

| Origin | Type | Resin Character |

|---|---|---|

| Vietnam (Nha Trang) | Black Kyara | Dark, shiny, sweet & cooling |

| Hainan | Purple Kyara | Purple spots, honey & creamy scent |

| Cambodia | Pusana | Brown oil lines, elegant floral aroma |

| Brunei | Soft Silk Green Kyara | Dark green oil, long-lasting minty scent |

FAQ: Common Questions About Agarwood CO2 Extraction Failure

Q1: Why did the agarwood supercritical CO₂ extraction fail?

A1: The raw material used was white wood agarwood, which contains extremely low resin content. Without sufficient resin, it is impossible to extract oleoresin or essential oil.

Q2: How can I identify whether agarwood is suitable for CO₂ extraction?

A2: Check for dark oil lines, strong fragrance, and the origin or species. High-resin agarwood has a distinctive aroma and resinous appearance. Low-resin white wood lacks both.

Q3: Can low oil content be compensated for by adjusting extraction parameters?

A3: No. Even with optimized pressure, temperature, and flow rate, oil-free or low-resin agarwood will not yield extractable oleoresin. Raw material quality is critical.

Q4: Does white wood agarwood have any value?

A4: White wood has no commercial or medicinal value. It lacks resin, aroma, and is not suitable for essential oil extraction or incense production.

Q5: Which agarwood types are suitable for supercritical CO₂ extraction?

A5: Recommended high-resin types include:

- Black Kyara from Nha Trang, Vietnam (dark resin, sweet-cooling aroma)

- Purple Kyara from Hainan, China (purple oil spots, honey-milky scent)

- Pusana from Cambodia (yellow-brown oil lines, floral aroma)

- Green Kyara from Brunei (dark green oil, long-lasting minty coolness)

Trusted by Global Clients

Our CO2 extraction systems have been sold to over 30 countries, including the USA, Germany, Thailand, and Australia. From start-up brands to well-known herbal extract manufacturers, our customers trust us for:

- Reliable equipment performance

- Excellent technical support

- One-stop turnkey solutions

- Remote installation guidance and training

Supercritical CO2 Extraction Market Report

Contact Us

Looking for the right supercritical CO2 extraction equipment for your business? Contact us today for custom quotes, technical consultation, and free extraction process evaluation.

Email: [email protected]

WhatsApp/Phone: +86-134-8515-5519