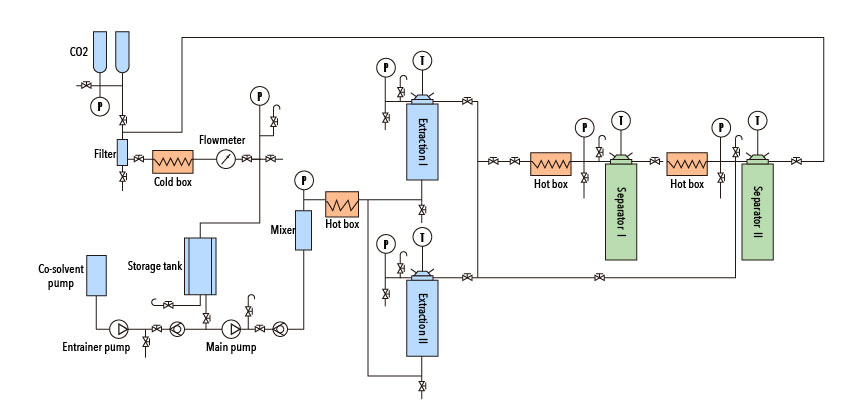

Looking for supercritical CO2 extraction equipment that can serve both laboratory research and small-scale production? The 10L+1L dual-extractor system is designed to meet the dual demands of R&D and commercial trial runs. With its smart dual-vessel configuration, this equipment delivers flexibility, precision, and cost-efficiency, making it a perfect choice for essential oil producers, herbal extract developers, and functional ingredient manufacturers.

Key Advantages of 10L+1L Supercritical CO2 Extraction Equipment

Dual-Scale Operation: Lab + Production in One Machine

The most significant advantage of the 10L+1L configuration is its dual functionality. It includes:

- A 1-liter extraction vessel dedicated to small-volume lab testing and formulation development.

- A 10-liter vessel optimized for small-scale batch production, enabling pilot runs without scaling up to a full industrial unit.

With this setup, users can validate processes on a small scale and immediately apply them to commercial production, saving time, reducing waste, and accelerating market readiness.

Technical Specifications at a Glance

The 10L+1L supercritical extraction system operates at 500 bar design pressure (400 bar working) with food-grade stainless steel construction for pharmaceutical compliance.

| Feature | Specification |

|---|---|

| Extraction Vessels | 1L + 10L (Independent or parallel operation) |

| Separator Vessels | 2 units, each with independent temperature/pressure control |

| Design Pressure | 500 bar |

| Working Pressure | Up to 400 bar |

| Temperature Range | Room temp to 85°C (PID controlled) |

| Automation | Optional PLC control with touch screen HMI |

| Material | Food-grade stainless steel (SUS304/SUS316) |

| Lifespan | Over 15 years (Certified pressure vessels) |

Why Choose 10L+1L for Supercritical CO2 Extraction?

1. Research-Backed Production

Use the 1L vessel to optimize parameters like pressure, temperature, and co-solvent ratio on small samples—then apply those findings directly to the 10L vessel for production, ensuring data consistency and reducing scale-up risks.

2. Significant Cost Savings

Avoid the high operating cost of running large CO2 systems during R&D. With 1L testing, CO2 consumption and raw material use are minimized. Once optimized, the 10L vessel delivers efficient batch output without the need for additional equipment.

3. Faster Time-to-Market

Seamless transition from lab validation to commercial trial accelerates your R&D cycle. There’s no need to redesign or recalibrate your process when moving to the 10L unit—it’s all built-in.

4. Flexible Applications Across Industries

Whether in essential oils, nutraceuticals, cosmetics, or pharmaceuticals, this dual-chamber CO2 extraction system gives you the control and adaptability needed to handle different botanical materials with precision.

Applications and Target Materials

| Industry | Common Extraction Targets |

|---|---|

| Essential Oils | Lavender, frankincense, agarwood, rose |

| Herbal Medicine | Salvia miltiorrhiza, ginseng, Ganoderma |

| Food & Beverage | Black pepper, ginger, hop resin |

| Cosmetics | Calendula, rosemary, chamomile |

Real-World Benefits from Our Clients

Many startups, university labs, and boutique producers have adopted our 10L+1L supercritical CO2 extractor for its unmatched versatility and reliability. Clients especially appreciate its:

- Compact footprint for limited lab space

- Stable performance during long extraction runs

- Easy cleaning and switch-over between small and large batches

- Excellent ROI for both short-term trials and long-term use

Designed for Scalability and Global Compliance

• Pressure vessels comply with ASME / CE / PED standards

• Supports GMP compliance for nutraceutical or pharmaceutical applications

• Modular design for easy expansion or customization

• Worldwide installation and after-sales service support

Frequently Asked Questions (FAQ)

1. What is a 10L+1L supercritical CO2 extraction machine?

It’s a dual-vessel CO2 extraction system combining a 10-liter vessel for small-scale production and a 1-liter vessel for lab-scale testing. It allows flexible switching between research and commercial use.

2. Who should use this type of extraction equipment?

This extractor is ideal for R&D labs, startup companies, essential oil producers, and manufacturers looking to bridge lab validation with small-batch market release.

3. What materials can be processed with this machine?

Common materials include lavender, agarwood, rosemary, ginseng, black pepper, and other botanicals used in essential oils, cosmetics, and herbal extracts.

4. Can the 10L and 1L vessels operate independently?

Yes. Both extraction vessels can run independently or in sequence. This makes it highly efficient for multi-formulation testing and flexible production scheduling.

5. What is the working pressure and temperature range?

The machine is designed for up to 500 bar, with a recommended working pressure of ≤400 bar. Temperature is adjustable up to 85°C using PID-controlled electric heating.

6. Is this equipment suitable for GMP or pharmaceutical use?

Yes. The system can be customized with food/pharma-grade stainless steel (SUS316), and pressure vessels are certified to meet GMP, CE, or ASME requirements.

7. What kind of control system does it offer?

A PLC automatic control system with a touchscreen HMI is optional. Manual operation is also available, depending on the user’s preference and budget.

8. How much raw material can the 10L vessel handle per batch?

Typically, the 10L vessel can handle around 3 – 6 kg of dry plant material per batch, depending on bulk density and grind size.

9. Is technical support and training provided?

Yes. We provide remote technical guidance, installation support, and video training. On-site support can also be arranged if needed.

10. How do I request a quote or trial test?

Simply contact us via email or WhatsApp. We’ll provide a detailed quotation, process consultation, and you are welcome to bring raw material for on-site testing.

Trusted by Global Clients

Our CO2 extraction systems have been sold to over 30 countries, including the USA, Germany, Thailand, and Australia. From start-up brands to well-known herbal extract manufacturers, our customers trust us for:

- Reliable equipment performance

- Excellent technical support

- One-stop turnkey solutions

- Remote installation guidance and training

Supercritical CO2 Extraction Market Report

Request a Quote or Schedule a Demo

Whether you’re a research institution or a startup preparing for small-batch launches, our 10L+1L supercritical CO2 extraction equipment offers unmatched value. Contact us today to receive a tailored quotation, technical catalog, or to schedule an on-site trial.

Email: [email protected]

WhatsApp / WeChat: +86-134-8515-5519