As the global demand for medical and recreational cannabis grows, producers must choose the right extraction method. The CO2 extraction equipment difference compared to BHO (Butane Hash Oil) extraction lies in safety, efficiency, and purity. Both methods dominate the industry today but represent two very different technical paths. While BHO prioritizes high concentration and lower costs, supercritical CO2 extraction emphasizes clean, safe, and highly controlled extraction. Understanding these methods helps manufacturers, researchers, and consumers make informed decisions.

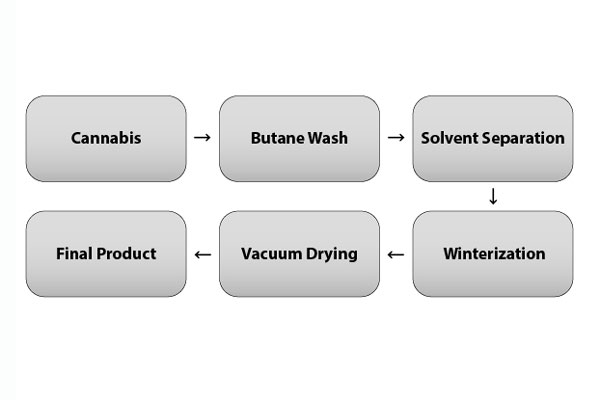

1. BHO (Butane Hash Oil) Extraction Process

Simplified Flow:

Cannabis → Butane Wash → Solvent Separation → Winterization → Vacuum Drying → Final Product

Key Steps:

- Material Preparation: High-quality dry or fresh-frozen cannabis is ground to increase surface contact.

- Butane Extraction: Liquid butane flows through cannabis material in a closed loop. It dissolves cannabinoids and terpenes due to its strong non-polar solvency.

- Solvent Recovery: Heat or thin-film evaporation recovers butane for reuse. The extract remains as a thick, dark concentrate.

- Winterization (Optional): Dissolving the extract in ethanol and freezing allows waxes and fats to solidify and be filtered out.

- Vacuum Drying: Residual solvents are removed under low heat and pressure to protect volatile terpenes.

- Final Product: The result may be shatter, budder, wax, or live resin, packaged under inert conditions to preserve flavor.

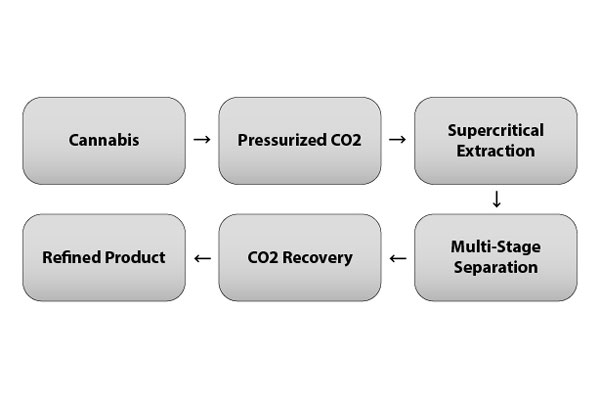

2. Supercritical CO2 Extraction Process

Simplified Flow:

Cannabis → Pressurized CO2 → Supercritical Extraction → Multi-Stage Separation → CO2 Recovery → Refined Product

Key Steps:

- Material Preparation: Dry cannabis (moisture <10%) is ground and packed into a high-pressure extraction vessel.

- CO2 Pressurization: Food-grade CO2 is brought above 31.1°C and 7.38 MPa to enter the supercritical phase—both a gas and a liquid.

- Supercritical Extraction: CO2 dissolves target compounds. Solubility can be tuned by adjusting pressure and temperature, allowing for selective extraction (e.g., terpenes first, cannabinoids later).

- Multi-Stage Separation: The CO2 mixture passes through multiple separators. Pressure and temperature shifts allow compounds to precipitate step by step—first terpenes, then cannabinoids, finally waxes or pigments. How to perform multi-stage separation [For more information, please click here to view Multi-Stage Extraction and Separation in Supercritical CO2 Extraction Using Pure CO2]

- CO2 Recovery: Remaining CO2 is cooled and liquefied for reuse, making the process efficient and eco-friendly.

- Post-Processing: Extracts may be dewaxed, bleached, or distilled depending on product requirements. CO2 extracts are used in CBD oils, edibles, skincare, and pharmaceuticals.

3. Key Process Differences

| Step | BHO Extraction | CO2 Extraction |

|---|---|---|

| Solvent | Liquid butane | Supercritical CO2 |

| Principle | Solvent evaporation + winterization | Solubility tuning + pressure separation |

| Purification | Requires vacuum drying | Optional dewaxing/distillation |

| Residual Solvent | High risk, must test | No residual solvent risk |

| Flavor Retention | Depends on care | Excellent with low-temp extraction |

| Safety | High risk (flammable) | Very safe (inert, non-flammable) |

4. Equipment and Solvent Comparison

| Feature | BHO | CO2 Extraction |

|---|---|---|

| Solvent Type | Butane/Propane | Carbon Dioxide |

| State | Flammable gas under normal conditions | Supercritical fluid under high pressure |

| Selectivity | Low, extracts most lipids/waxes | Tunable selectivity via pressure/temp |

| Equipment | Simple (tubes, vacuum ovens) | Complex (high-pressure pumps, separators) |

| Cost | Lower | Higher |

| Residual Risk | Significant | Minimal |

| Safety | Requires explosion-proof setup | Safe in most industrial environments |

5. Product Quality and Application Differences

| Attribute | BHO Extract | CO2 Extract |

|---|---|---|

| Speed | Very fast | Slower |

| Potency | Up to 80%+ THC | High-purity CBD/THC possible |

| Terpene Retention | May lose during heating | Excellent with precise control |

| Lipid/Wax Extraction | High, needs post-processing | Controlled, often minimal |

| Flavor Consistency | Varies by batch | Highly consistent |

| Forms | Shatter, wax, crumble, resin | Oils, isolates, full-spectrum distillates |

| Applications | Recreational concentrates | Medical-grade oils, foods, cosmetics |

6. Summary of Core Benefits and Use Cases

BHO Advantages:

- Lower startup cost

- Very fast extraction

- Extremely high potency concentrates

- Excellent flavor in live resin

- Popular in recreational markets

CO2 Extraction Advantages:

- Safe and non-toxic solvent

- Precise and customizable extraction

- No residual solvent issues

- High consistency and product purity

- Ideal for medical, wellness, and premium consumer products

7. Final Thoughts: Choose Based on Your Goals

The CO2 extraction equipment difference versus BHO isn’t just about technology—it’s about aligning with business needs and regulatory standards. BHO is ideal for fast, potent recreational extracts but carries higher risks. Supercritical CO2 extraction offers unmatched safety, control, and product cleanliness, perfect for medical and high-end markets. Your decision should weigh investment capacity, market goals, and compliance priorities.

As extraction technologies evolve, both BHO and CO2 systems will continue to shape the future of cannabis processing.

For producers considering a CBD extraction production line, it’s crucial to plan carefully before installation. Our guide, Preparing for CBD Extraction Production Line Installation: Key Processes and Functions, covers everything from raw material preparation and supercritical CO₂ extraction to winterization, decarboxylation, and purification. By following these key steps, cannabis producers can ensure efficient, safe, and high-purity CBD oil production.

FAQs

Q1: What is the main difference between BHO and CO2 extraction equipment?

A1: The core CO2 extraction equipment difference lies in safety and purity. CO2 systems use high-pressure, non-toxic CO2, while BHO uses flammable solvents.

Q2: Which method is better for terpene preservation?

A2: CO2 extraction is superior for terpene retention, especially with low-temperature, low-pressure first-pass extraction stages.

Q3: Is CO2 extraction more expensive than BHO?

A3: Yes. CO2 equipment has higher upfront costs due to its complexity and pressure requirements, but it offers safer and cleaner results with better long-term consistency.

Trusted by Global Clients

Our CO2 extraction systems have been sold to over 30 countries, including the USA, Germany, Thailand, and Australia. From start-up brands to well-known herbal extract manufacturers, our customers trust us for:

- Reliable equipment performance

- Excellent technical support

- One-stop turnkey solutions

- Remote installation guidance and training

Supercritical CO2 Extraction Market Report

Contact Us

Looking for the right supercritical CO2 extraction equipment for your business? Contact us today for custom quotes, technical consultation, and free extraction process evaluation.

Email: [email protected]

WhatsApp/Phone: +86-134-8515-5519

You can view other models of supercritical CO2 extraction equipment [View More]