Traditional solvent extraction methods often rely on toxic organic solvents such as hexane, chloroform, and methanol. These solvents pose environmental hazards, health risks, and can leave harmful residues, especially when processing heat-sensitive compounds. In contrast, supercritical CO2 extraction offers a green, safe, and efficient alternative. It operates based on the supercritical CO2extraction principle, which takes advantage of CO2’s behavior above its critical temperature (31.1°C) and pressure (7.38 MPa), where it exhibits both gas-like diffusivity and liquid-like solvency. This unique duality enables selective and solvent-free extraction, making it an ideal technique for industries seeking sustainability without compromising performance.

1. Fundamental Principles

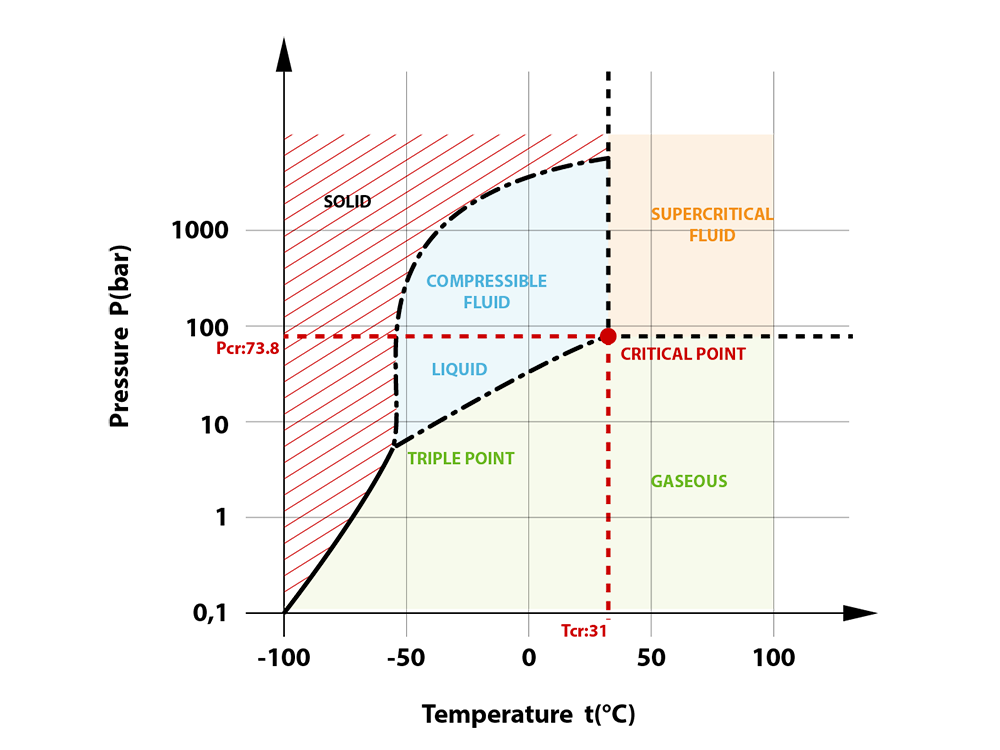

1.1 Supercritical State and Critical Point of CO2

The critical point of a substance is defined as the highest temperature and pressure at which its gas and liquid phases can coexist. For CO2, this point is 31.1°C and 7.38 MPa.

When CO2 is above this critical point, it becomes a supercritical fluid (SCF) with:

- Gas-like properties: low viscosity, high diffusivity, enhancing mass transfer and material penetration

- Liquid-like properties: high density, offering strong dissolving power

- Tunable properties: solvent strength can be adjusted continuously by changing pressure and temperature, which enables selective extraction

1.2 Solvent Power and Solubility

The dissolving ability of supercritical CO2 (scCO2) primarily depends on its density, which increases with pressure:

- High pressure → high density → dissolves heavier, non-polar compounds

- Low pressure → low density → suitable for volatile, low-molecular-weight compounds

Polarity limitation: Pure scCO2 is non-polar and poorly dissolves polar substances (e.g., sugars, amino acids). Adding co-solvents (entrainers) like ethanol or methanol (1–10 wt%) increases the system’s polarity and solubility range.

1.3 Mass Transfer Mechanism

The extraction process generally follows four steps:

- Internal diffusion: Solute migrates from inside the matrix to the surface

- Desorption: Solute detaches from the matrix surface

- Dissolution: Solute dissolves into the scCO2 phase

- Convection and transport: Flowing CO2 carries the solute away

The low viscosity and high diffusivity of scCO2 accelerate internal and external mass transfer, significantly improving extraction efficiency.

How-supercritical-co2-extraction-works [learn more]

2. Key Process Parameters

| Parameter | Effect |

|---|---|

| Pressure | Core factor controlling density and solvent power; higher pressure improves solubility for non-volatiles |

| Temperature | Dual effect: At constant pressure, higher temperature lowers density (↓ solubility); but at constant density, it increases solute vapor pressure (↑ solubility) |

| CO2 Flow Rate | Affects mass transfer driving force and residence time—must be optimized |

| Extraction Time | Should cover the target compound’s extraction curve to ensure completeness |

| Raw Material Particle Size | Smaller particles = higher surface area and faster diffusion |

| Co-solvent Type & Ratio | Determines the efficiency of polar compound extraction |

3. Technical Advantages

- High Selectivity: Adjustable temperature and pressure enable target-specific extraction

- Low-Temperature Operation: Near-room temperature preserves thermolabile compounds like vitamins and essential oils

- No Solvent Residue: CO2 evaporates easily at ambient conditions

- Safe and Eco-Friendly: CO2 is GRAS (Generally Recognized As Safe), recyclable, and non-flammable

- Oxidation Prevention: An Inert CO2 environment protects sensitive compounds from degradation

- Fast and Efficient: High diffusivity reduces extraction time compared to traditional methods

4. Industrial Applications

| Industry | Example Applications |

|---|---|

| Food & Beverage | Decaffeination of coffee/tea, hop extraction, citrus oils, edible oils (seed/fish) |

| Pharmaceuticals | Extraction of active pharmaceutical ingredients (APIs), herbal medicine (ginkgo, ginseng), antioxidants (rosemary), Omega-3 |

| Cosmetics | Natural pigments (carotenoids), waxes (jojoba), essential oils |

| Environmental | Soil remediation (hydrocarbons, pesticides), activated carbon regeneration |

| Analytical Chemistry | Sample preparation for HPLC, GC, and other analytical methods |

5. Challenges and Future Outlook

Current Challenges

- High capital investment for high-pressure equipment

- Separation complexity when co-solvents are used

- Difficulty in continuous large-scale processing

- Incomplete predictive models for multi-component systems

Future Directions

- Develop cost-effective, high-efficiency pressure systems

- Integrate auxiliary technologies (ultrasound, microwave, and enzymatic pretreatment)

- Expand solvent systems for polar compound extraction

- Explore alternatives like supercritical water (scH₂O) for broader applications

6. Conclusion

Supercritical CO2 extraction has emerged as a cornerstone technology in green chemistry and sustainable separation. Its unique solvent tunability, non-toxic nature, and compatibility with thermolabile materials make it ideal for applications across industries. While challenges remain in system cost and polar compound extraction, continued innovation in process design and hybrid techniques promises to unlock its full industrial potential. From high-value nutraceuticals to environmental remediation, scCO2 extraction stands at the forefront of clean technology in modern chemical engineering.

[Learn More] Solvent Recovery in Supercritical CO2 Extraction

Trusted by Global Clients

Our CO2 extraction systems have been sold to over 30 countries, including the USA, Germany, Thailand, and Australia. From start-up brands to well-known herbal extract manufacturers, our customers trust us for:

- Reliable equipment performance

- Excellent technical support

- One-stop turnkey solutions

- Remote installation guidance and training

Supercritical CO2 Extraction Market Report

Contact Us

Looking for the right supercritical CO2 extraction equipment for your business? Contact us today for custom quotes, technical consultation, and free extraction process evaluation.

Email: [email protected]

WhatsApp/Phone: +86-134-8515-5519

You can view other models of supercritical CO2 extraction equipment [View More]